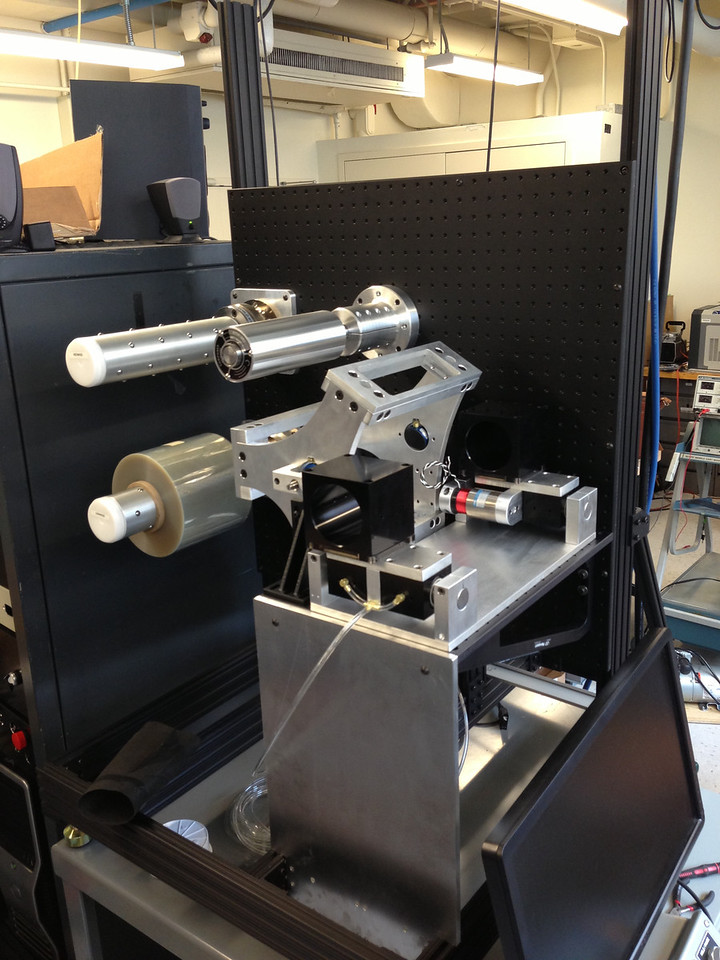

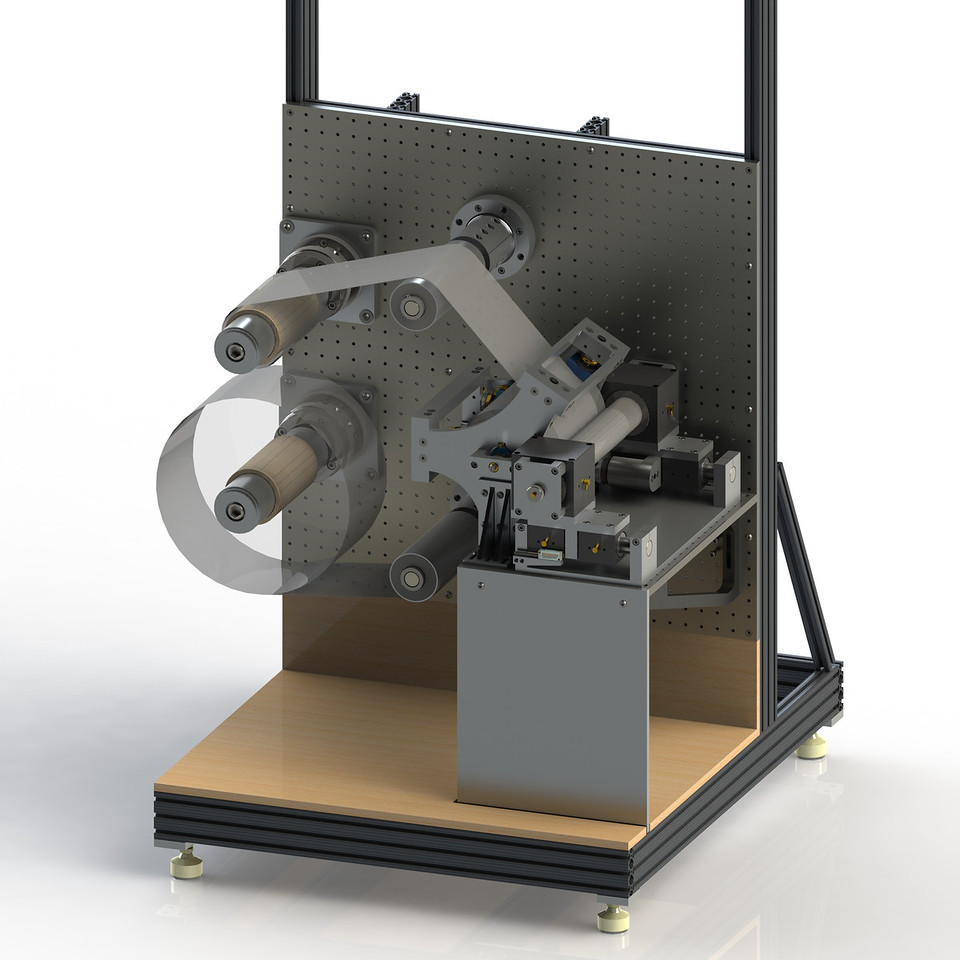

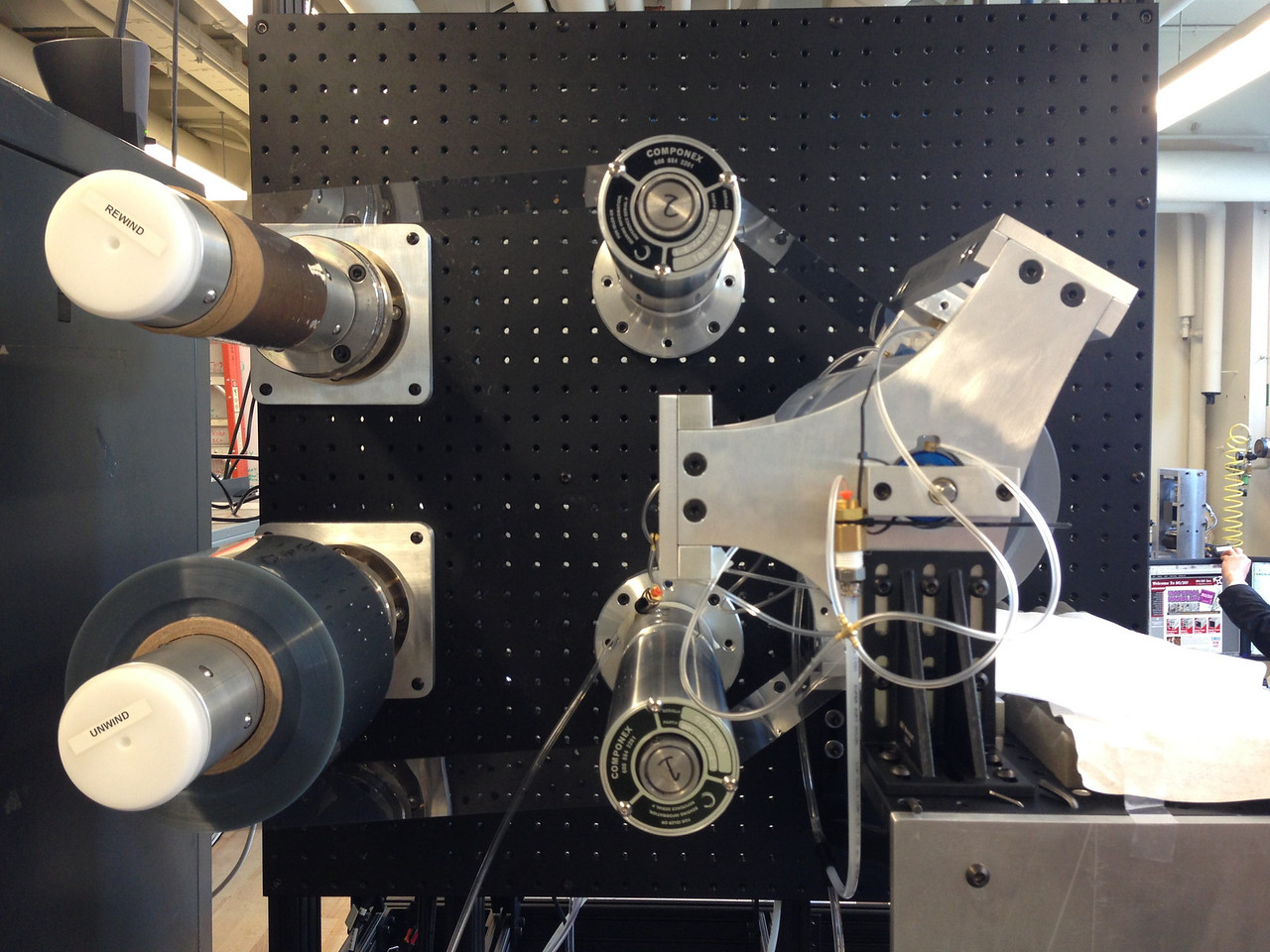

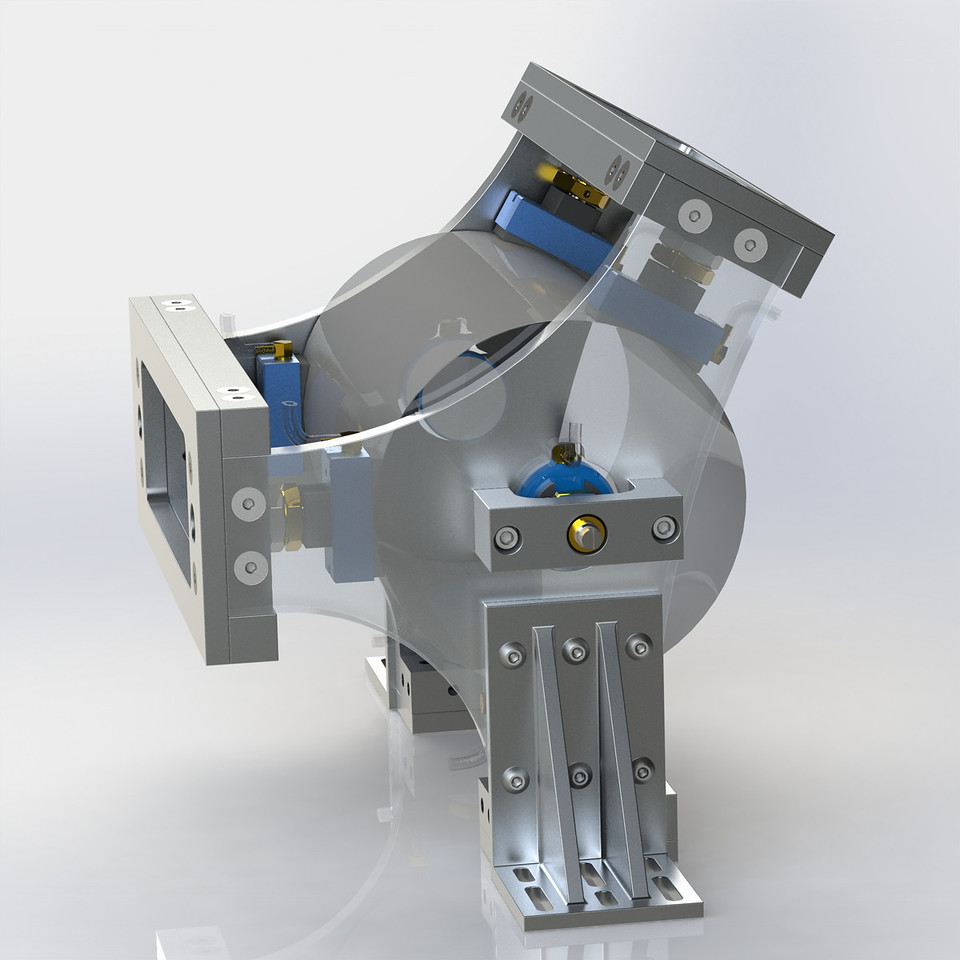

UFLEX MICROCONTACT PRINTER

Research Work in the Lab for Manufacturing and Productivity – Massachusetts Institute of Technology (2013)

Objective:

The goal is to design a machine that will demonstrate scale-up feasibility of a novel manufacturing process applicable to printed electronics and large-area surface modification.

Project Details:

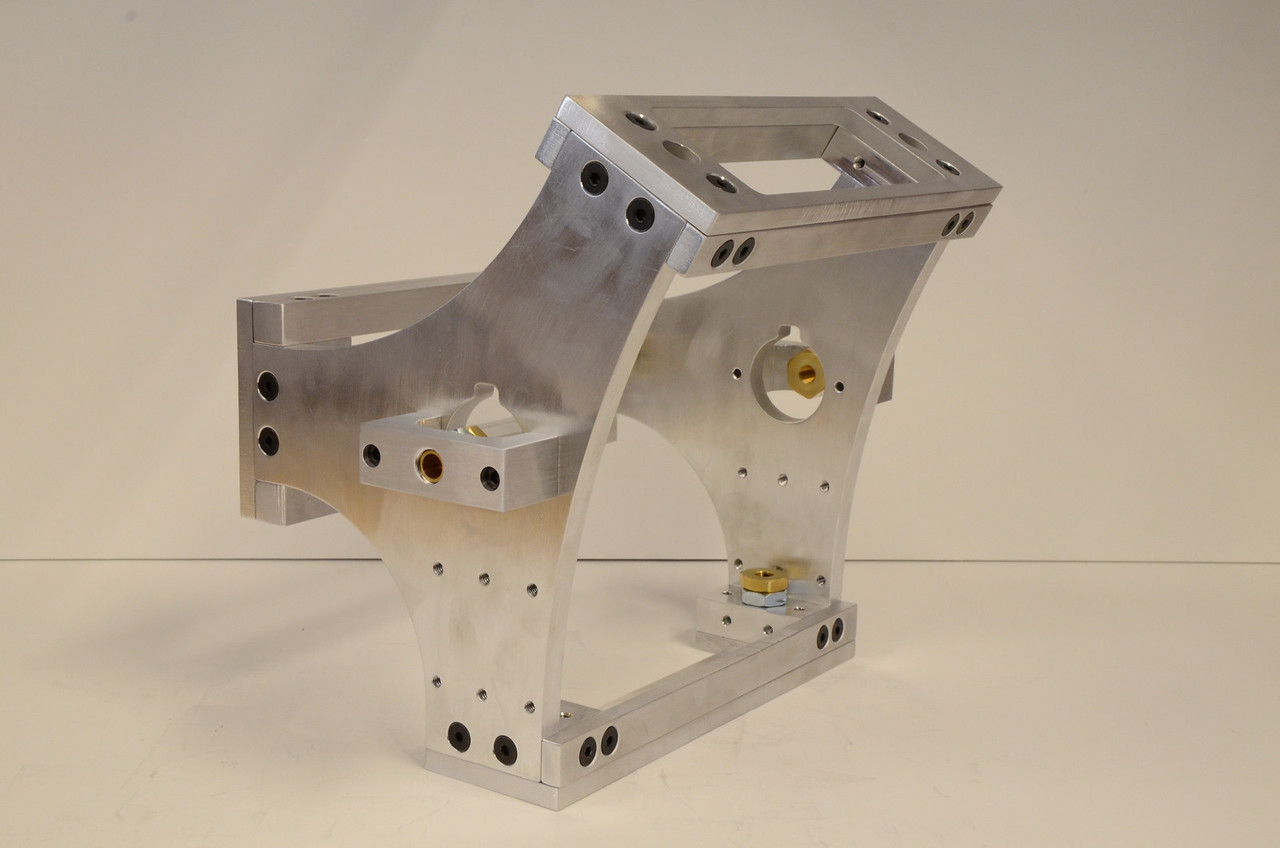

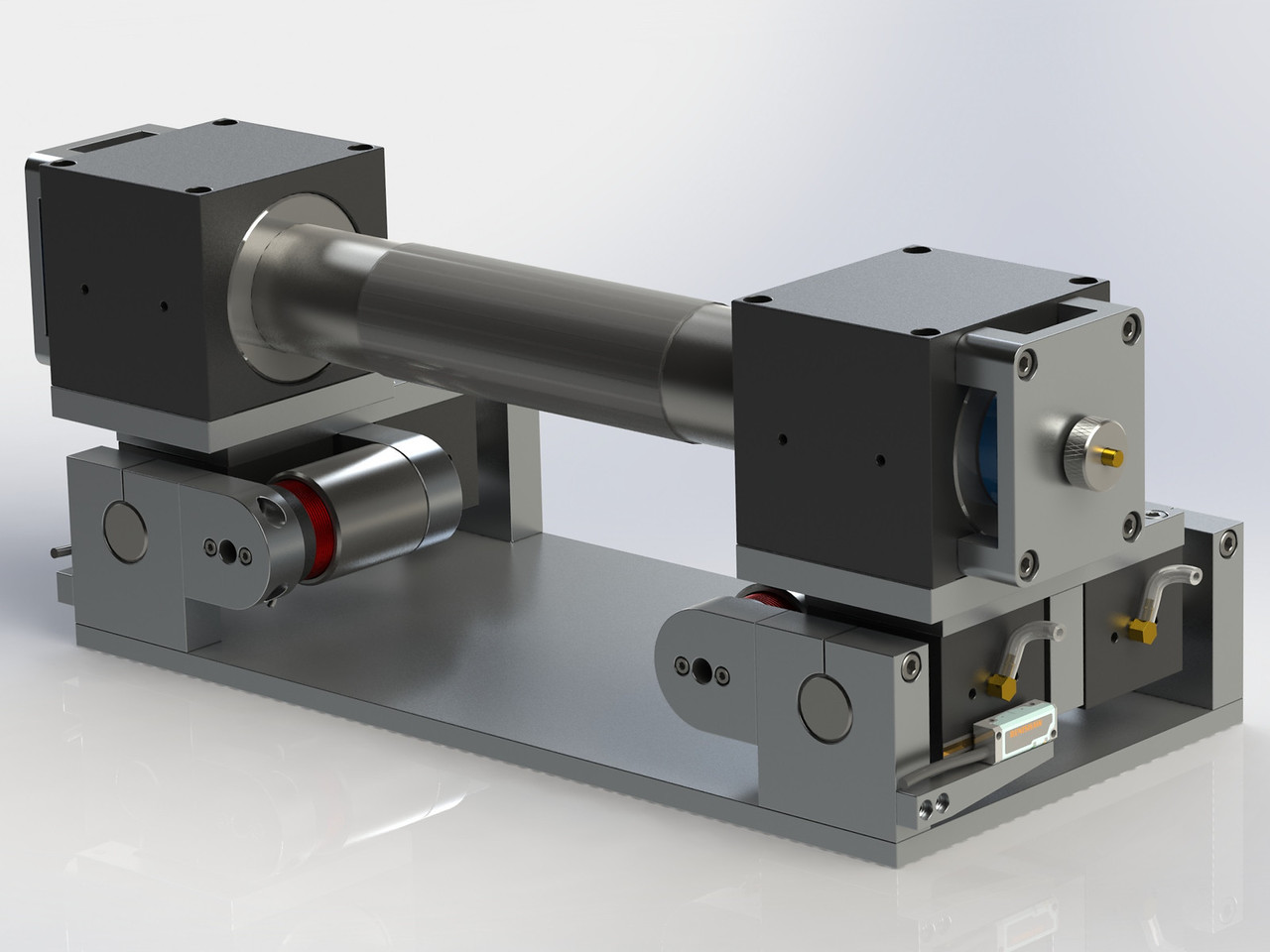

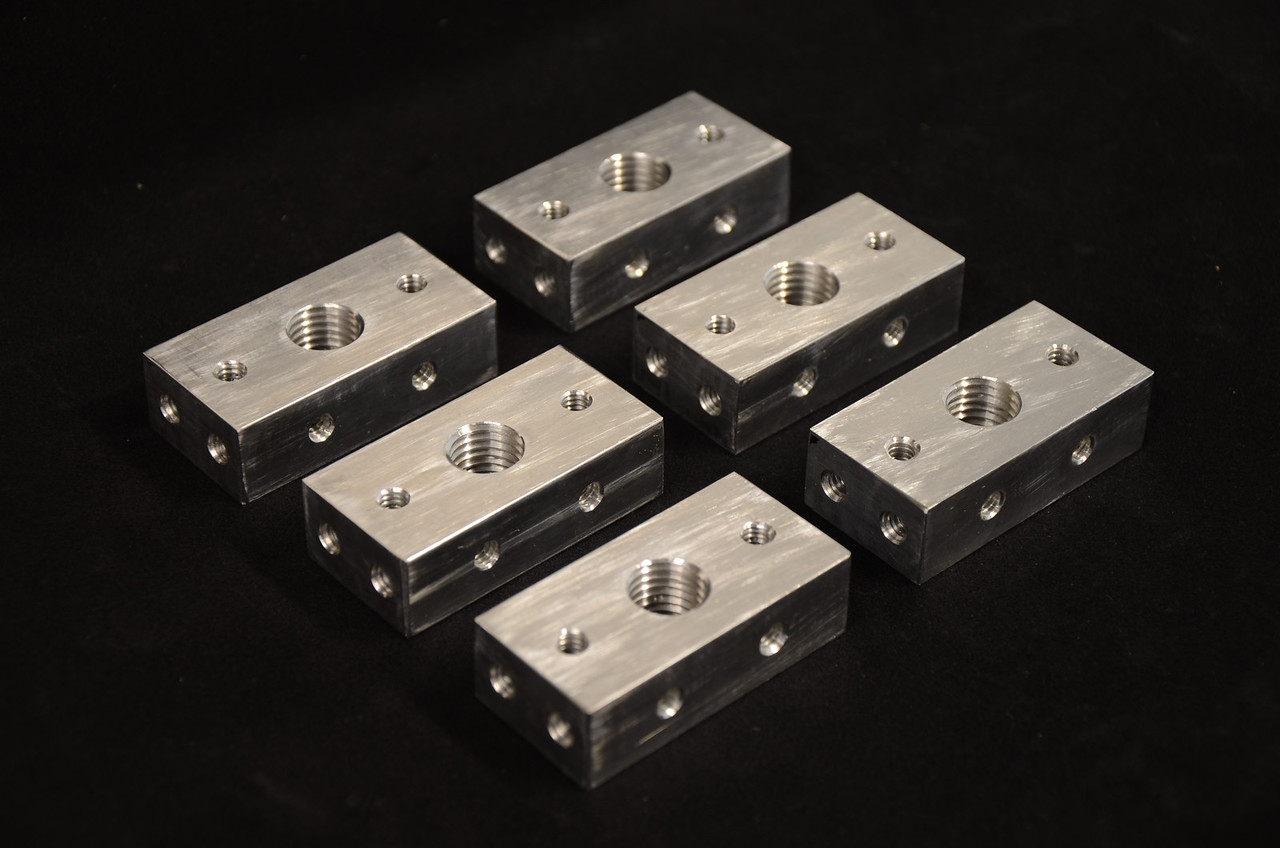

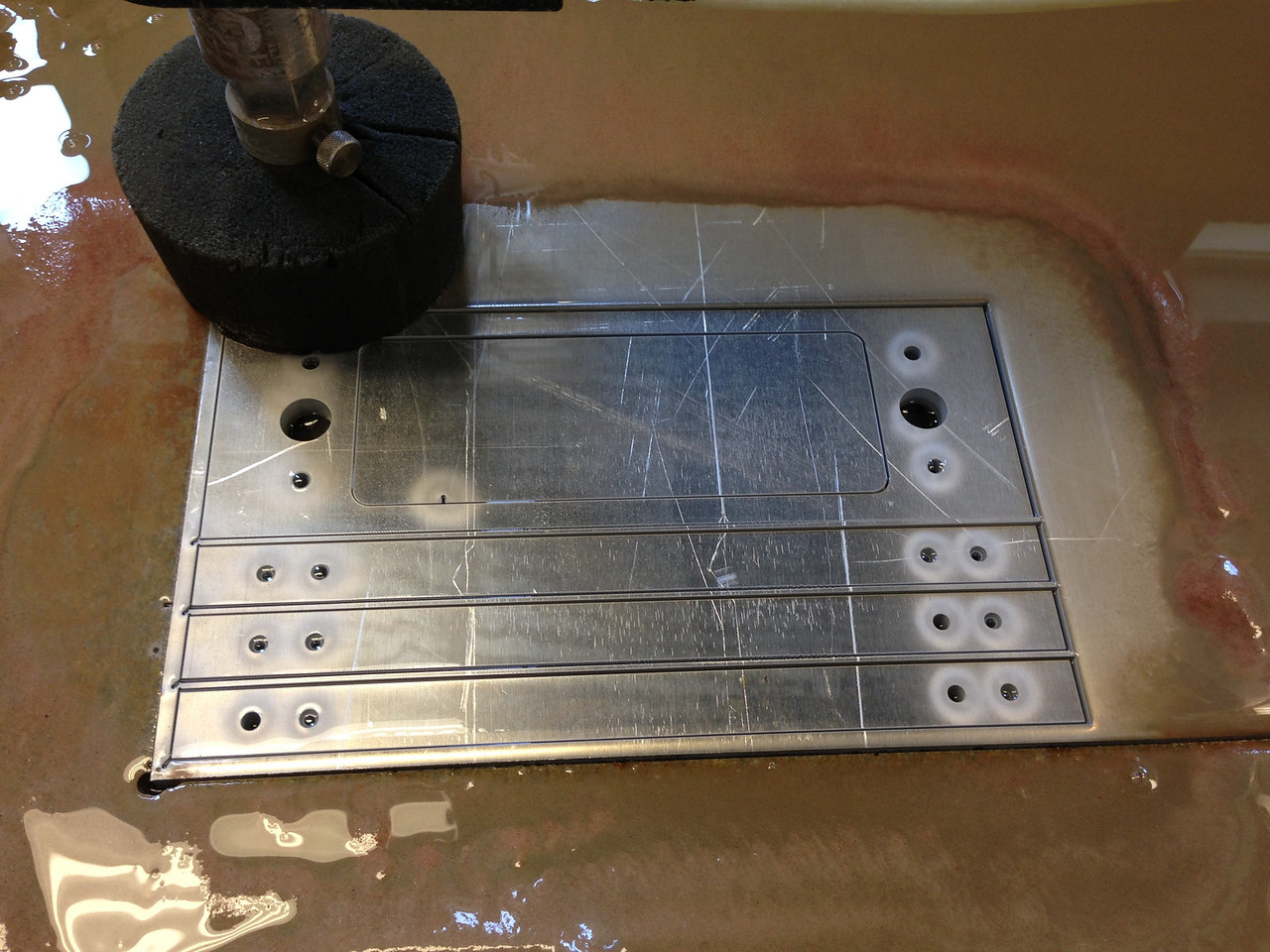

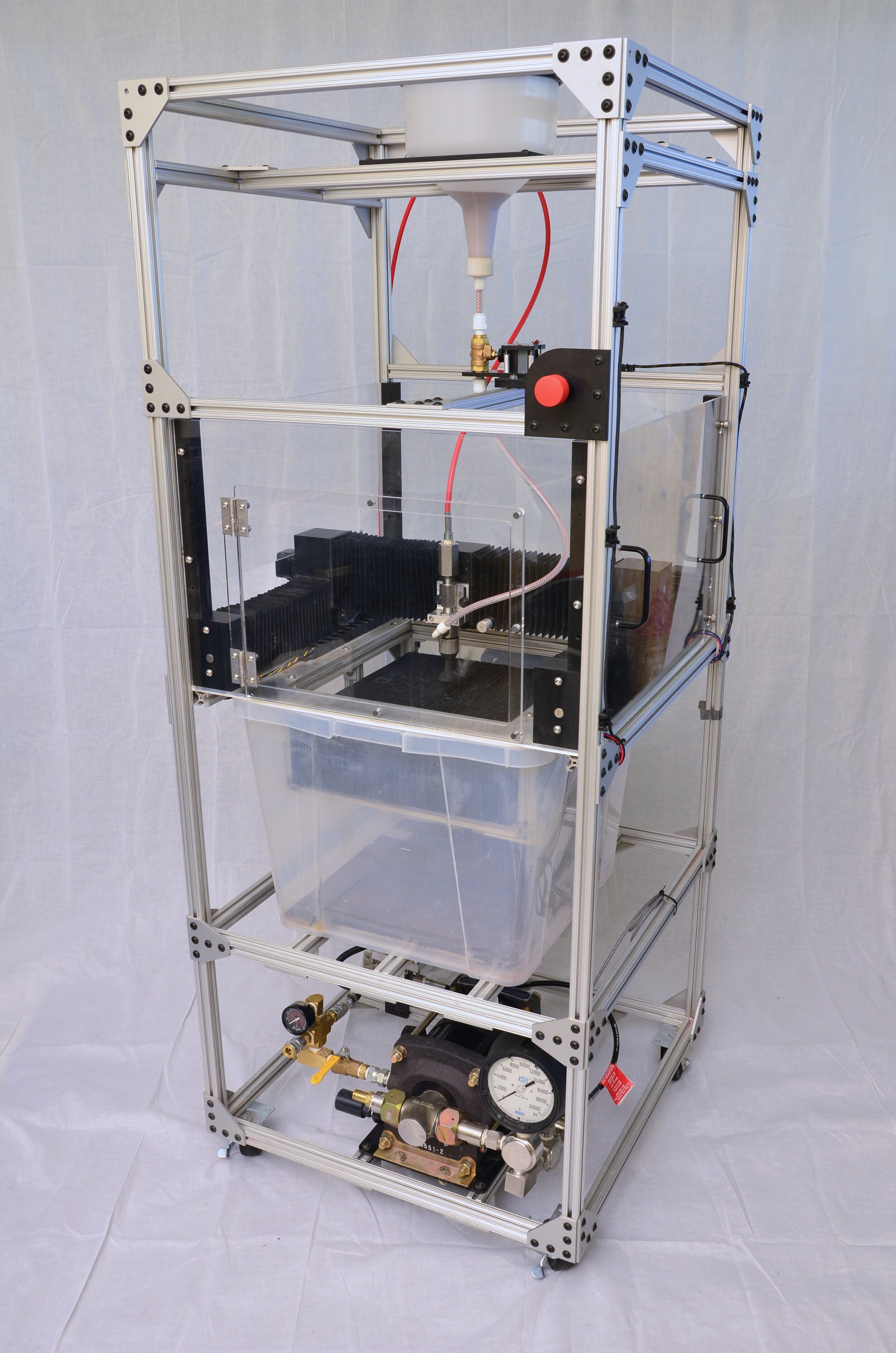

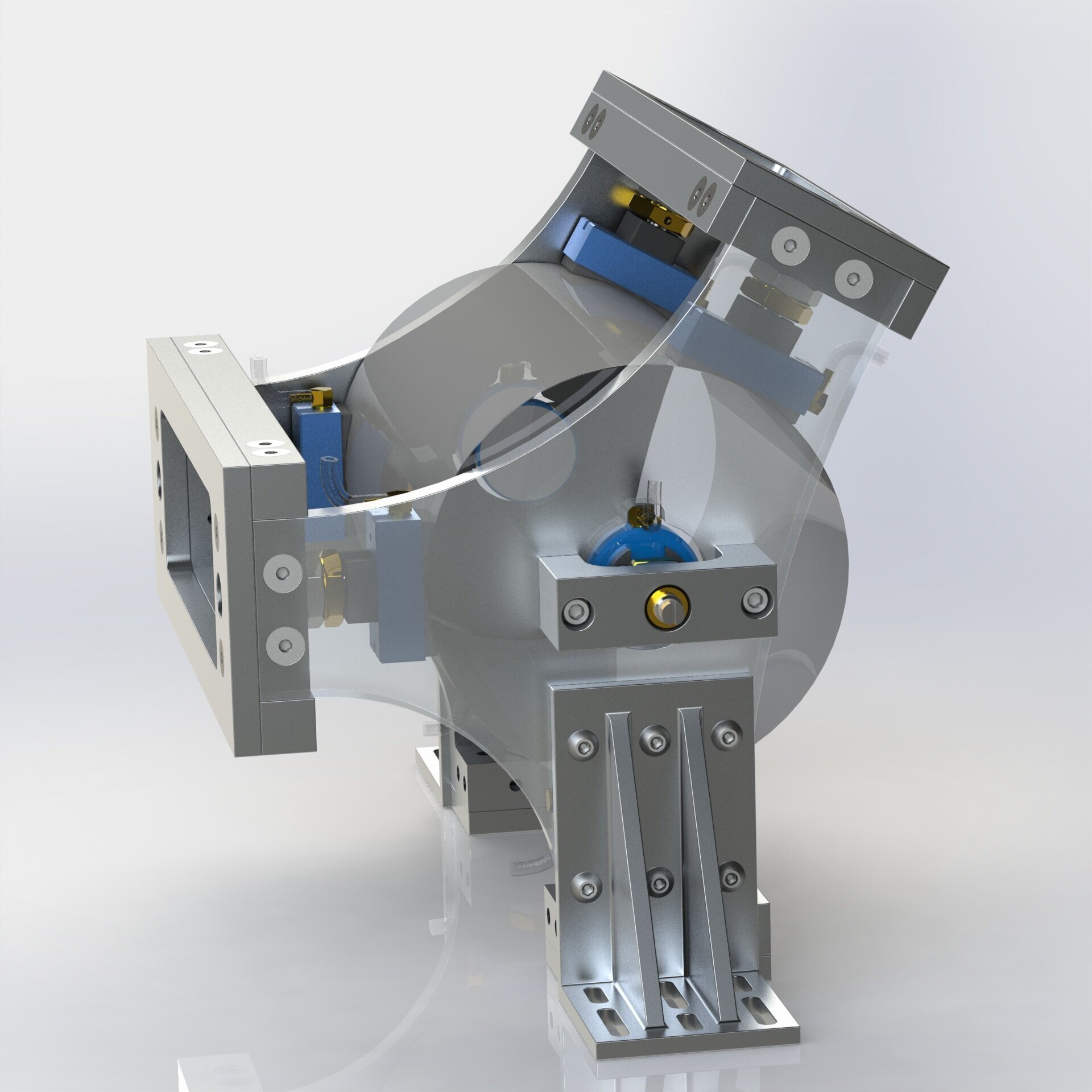

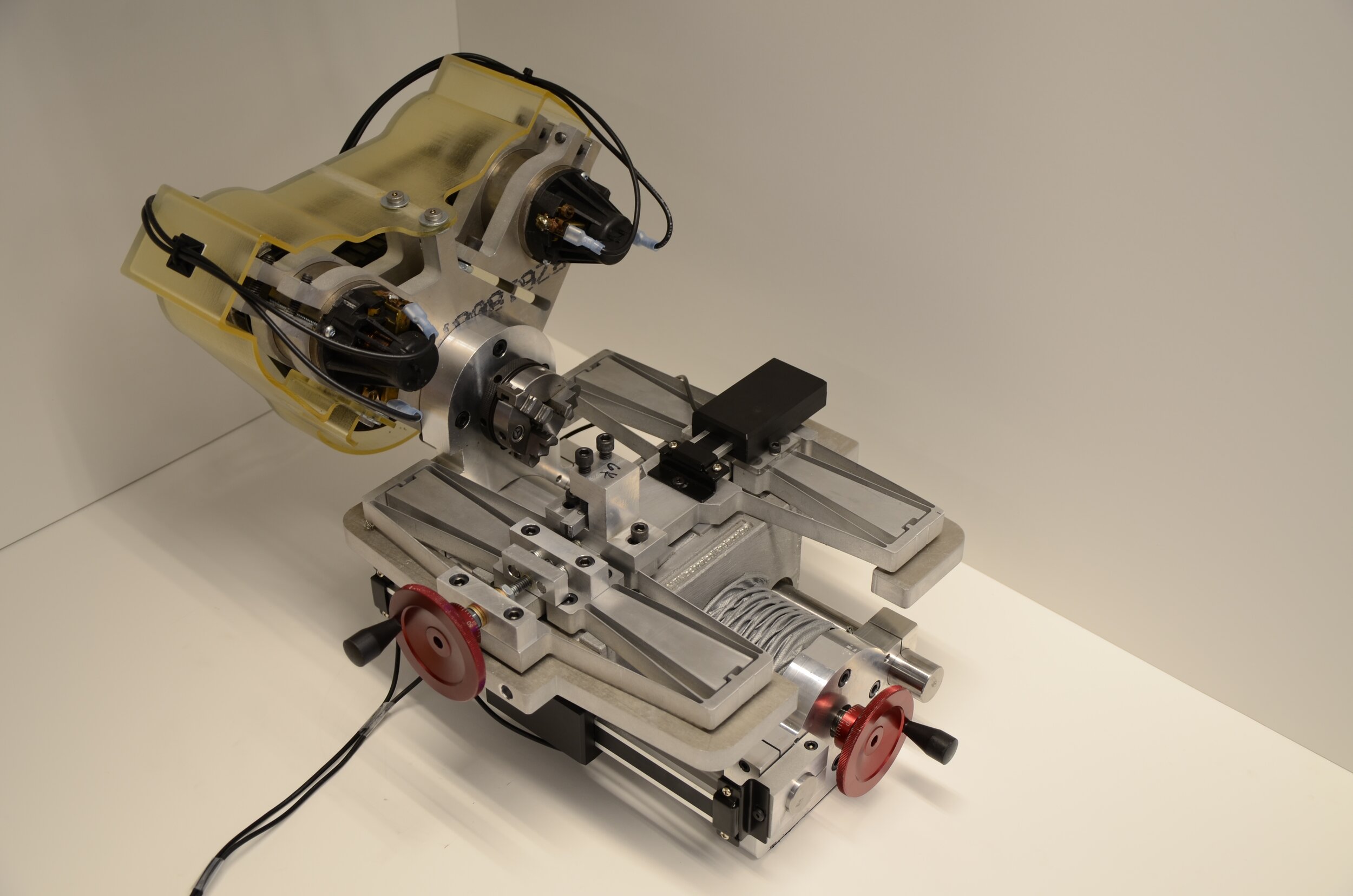

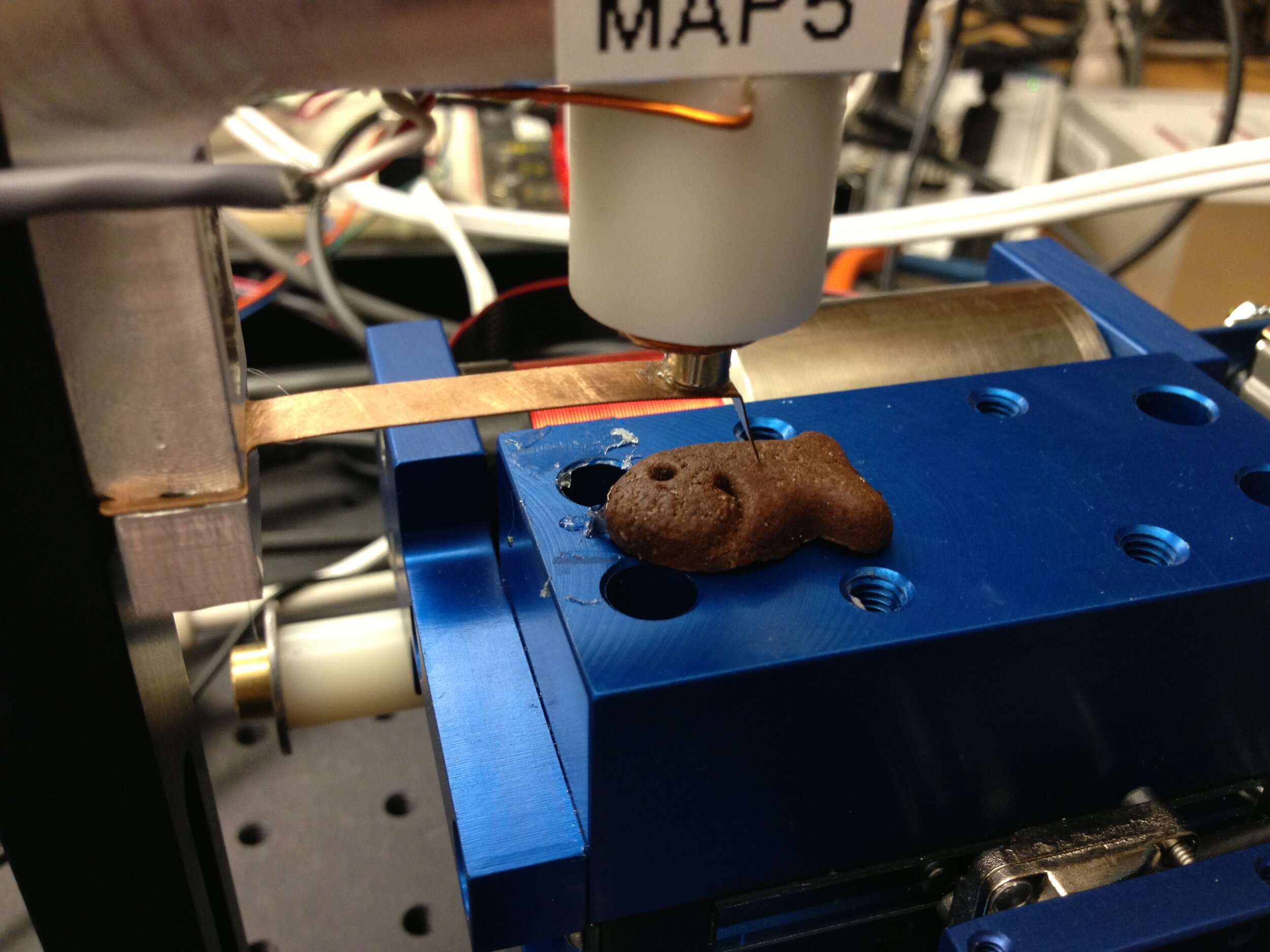

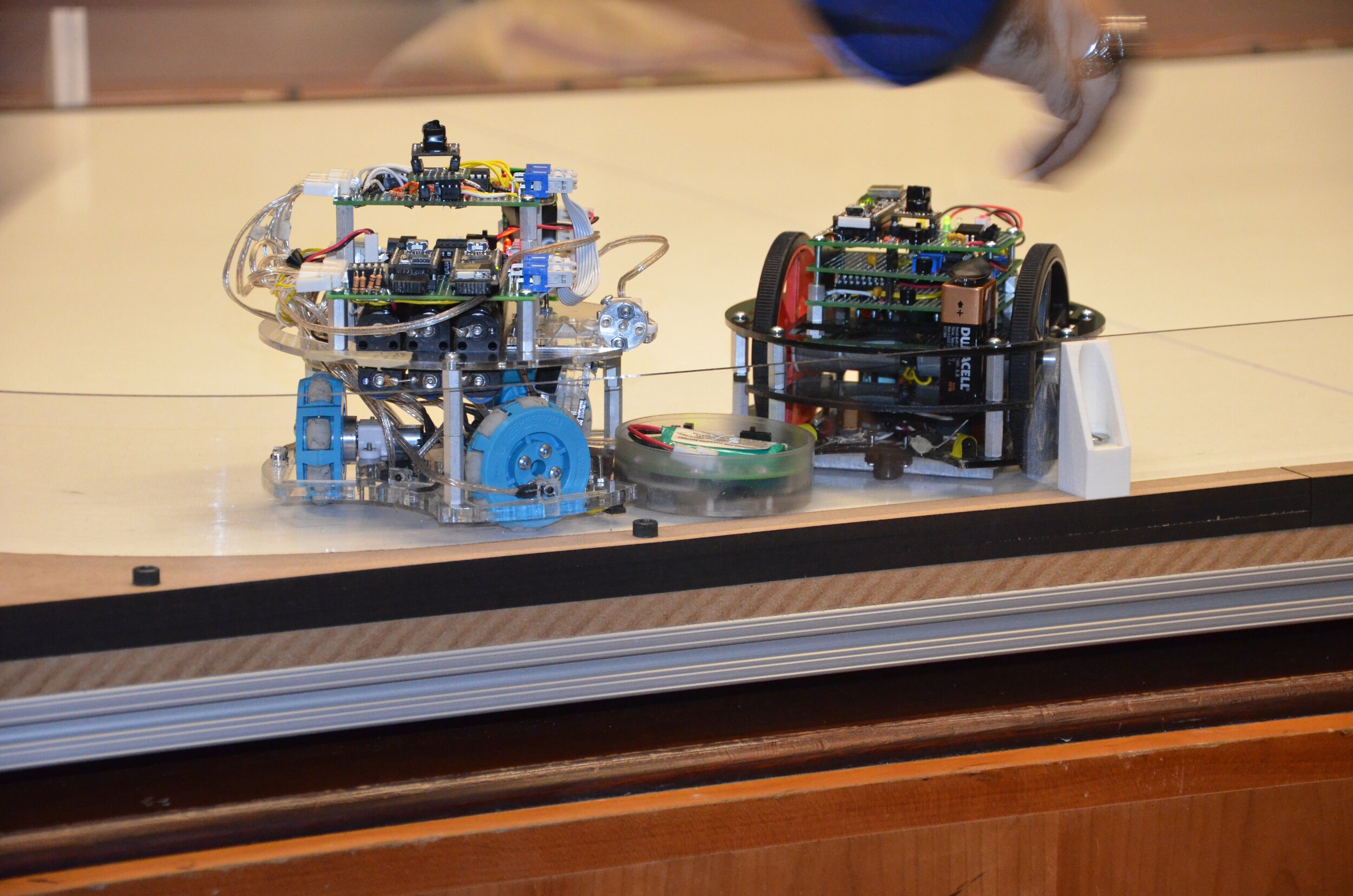

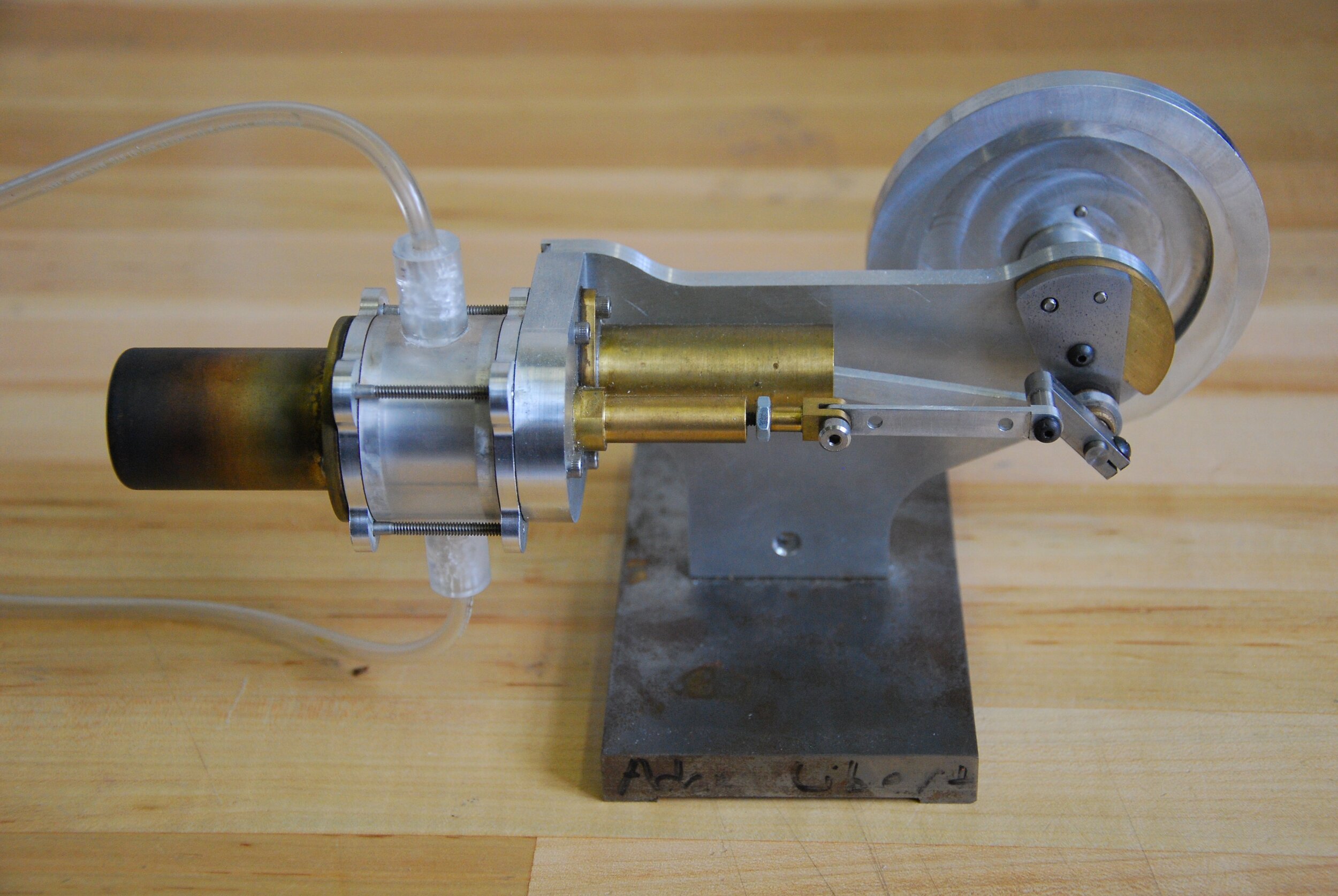

Microcontact printing is a process that uses a specially casted silicone stamp to print micron-scale features onto a substrate. It has been demonstrated in a variety of lab-scale settings, but my work is to design a machine to investigate how the process can be scaled up in a way that would enable large area, high rate manufacturing of engineered surfaces. Applications of this technology include flexible electronics displays, transparent conductors, distributed sensor systems, and bio-inspired surfaces. I’ve designed the machine to print silver nanoparticle inks and self-assembling monolayers onto a 6” wide, clear, PET plastic film at a web speed of up to one meter per second. In order to accomplish this goal, I’m working closely with two lab mates who are investigating electronics and cylindrical stamp casting.

Results:

This project served as the focus on my MIT Master’s Thesis, Precision control of cylindrical stamp contact in a continuous roll-to-roll microcontact printing machine. My thesis described the modeling of the continuous roll-to-roll print contact mechanics and the control algorithm used to give a robust process window. Though I have since left MIT, the machine I made lives on and has served as the testbed for following graduate students in the lab to continue research into the field of microcontact printing. It is still running today.