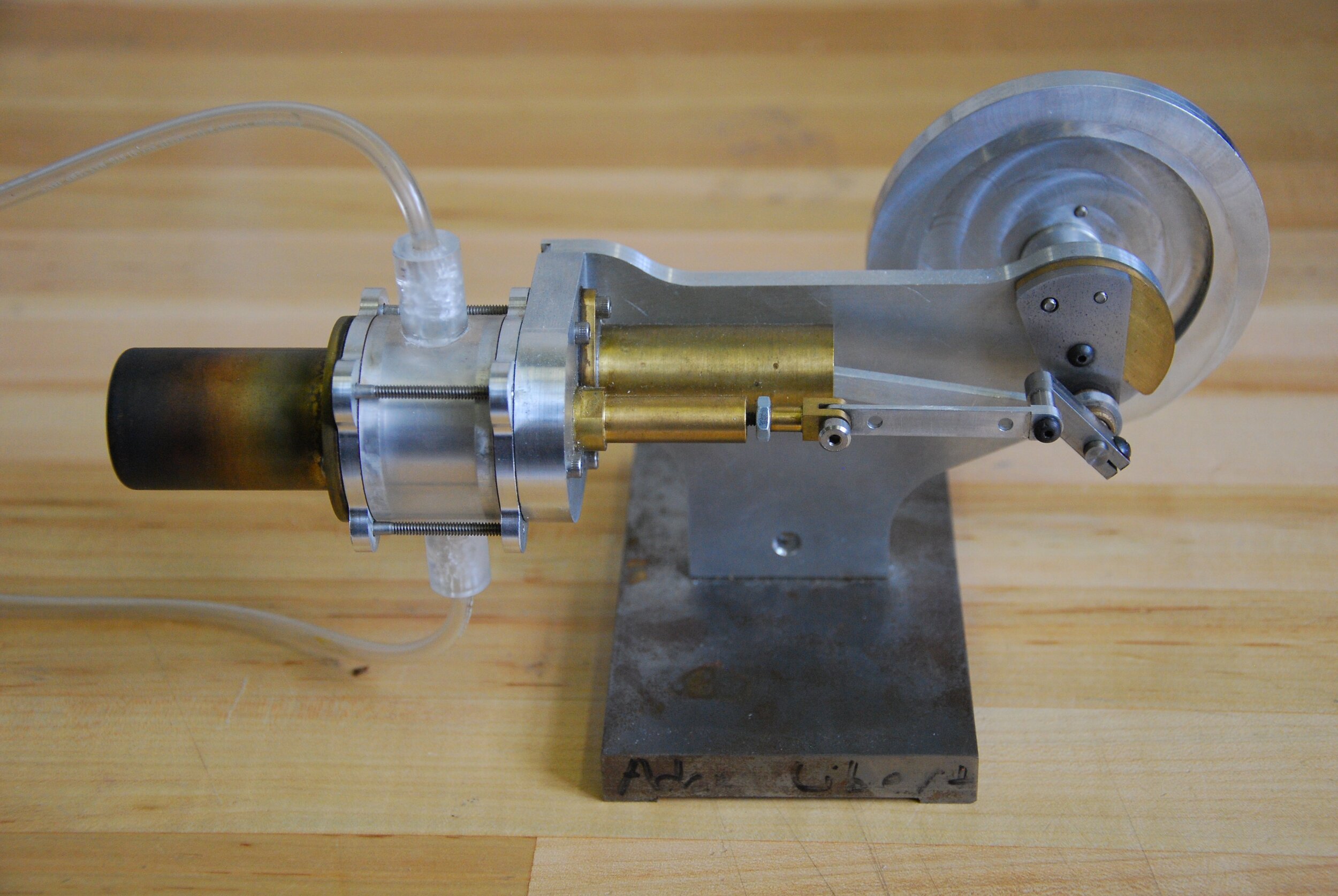

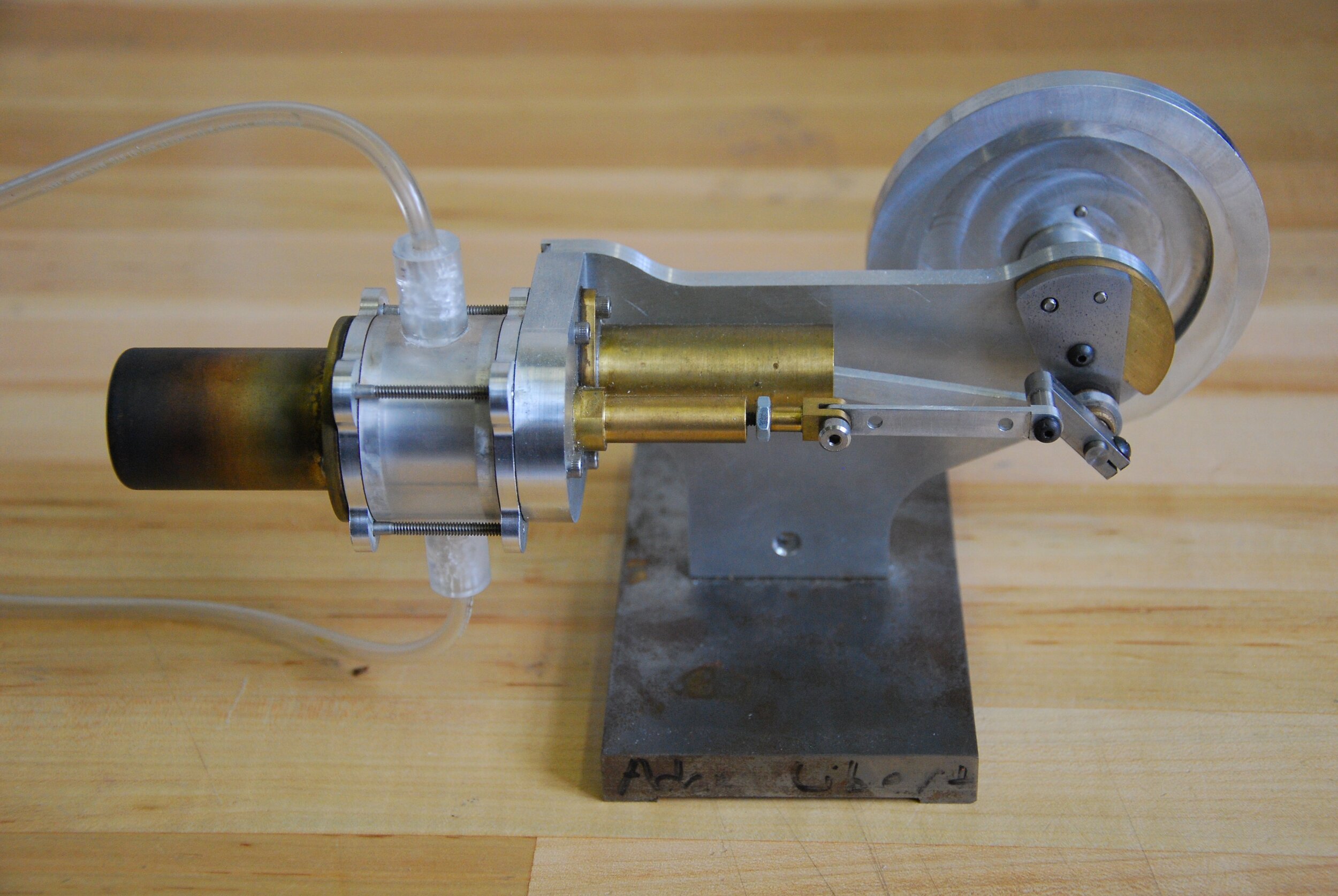

stirling engine

Mechanical Prototyping Course Project – University of Pennsylvania (2009)

Objective:

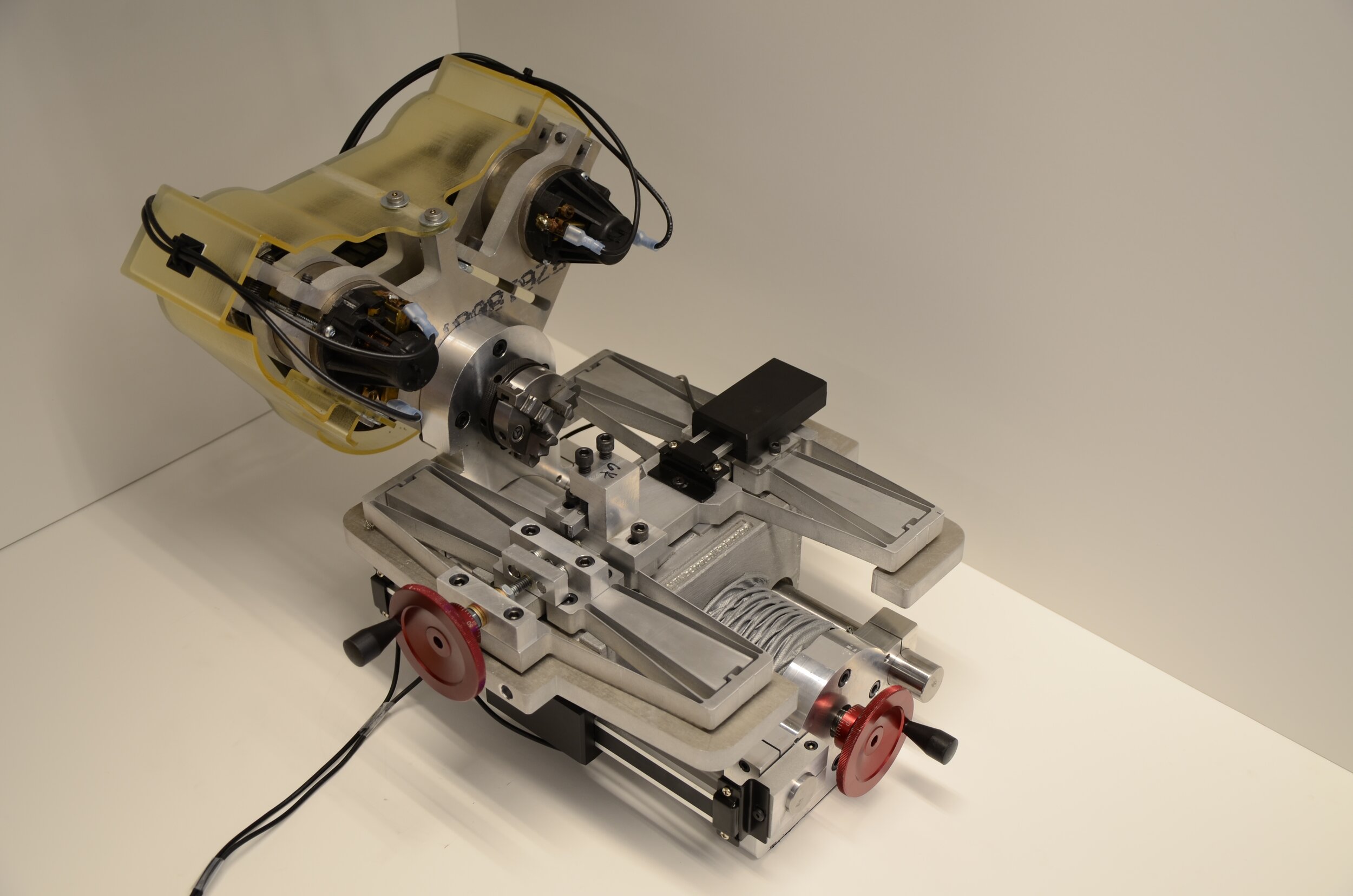

The goal of this project was to fabricate a working Stirling heat engine from scratch.

Project Details:

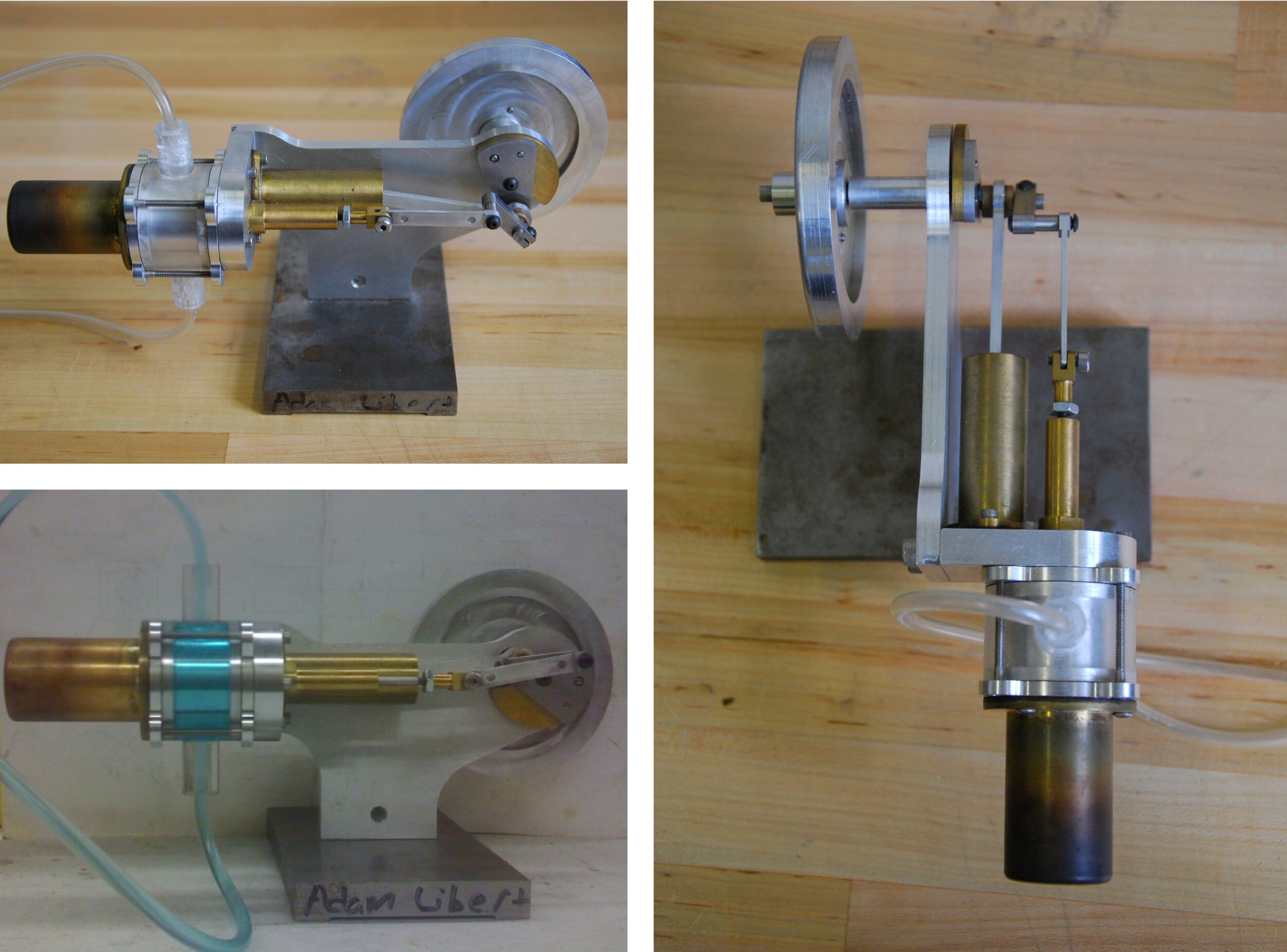

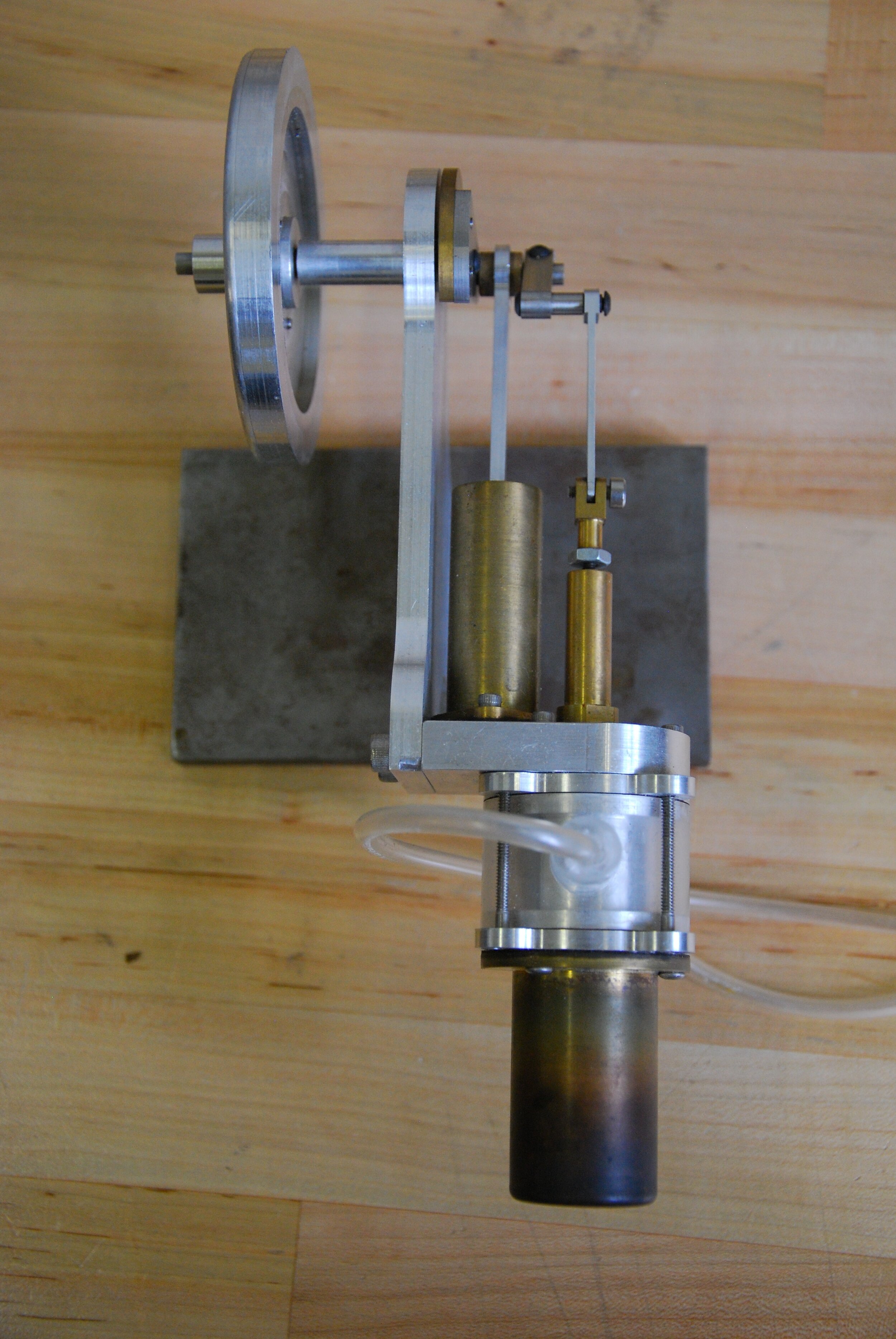

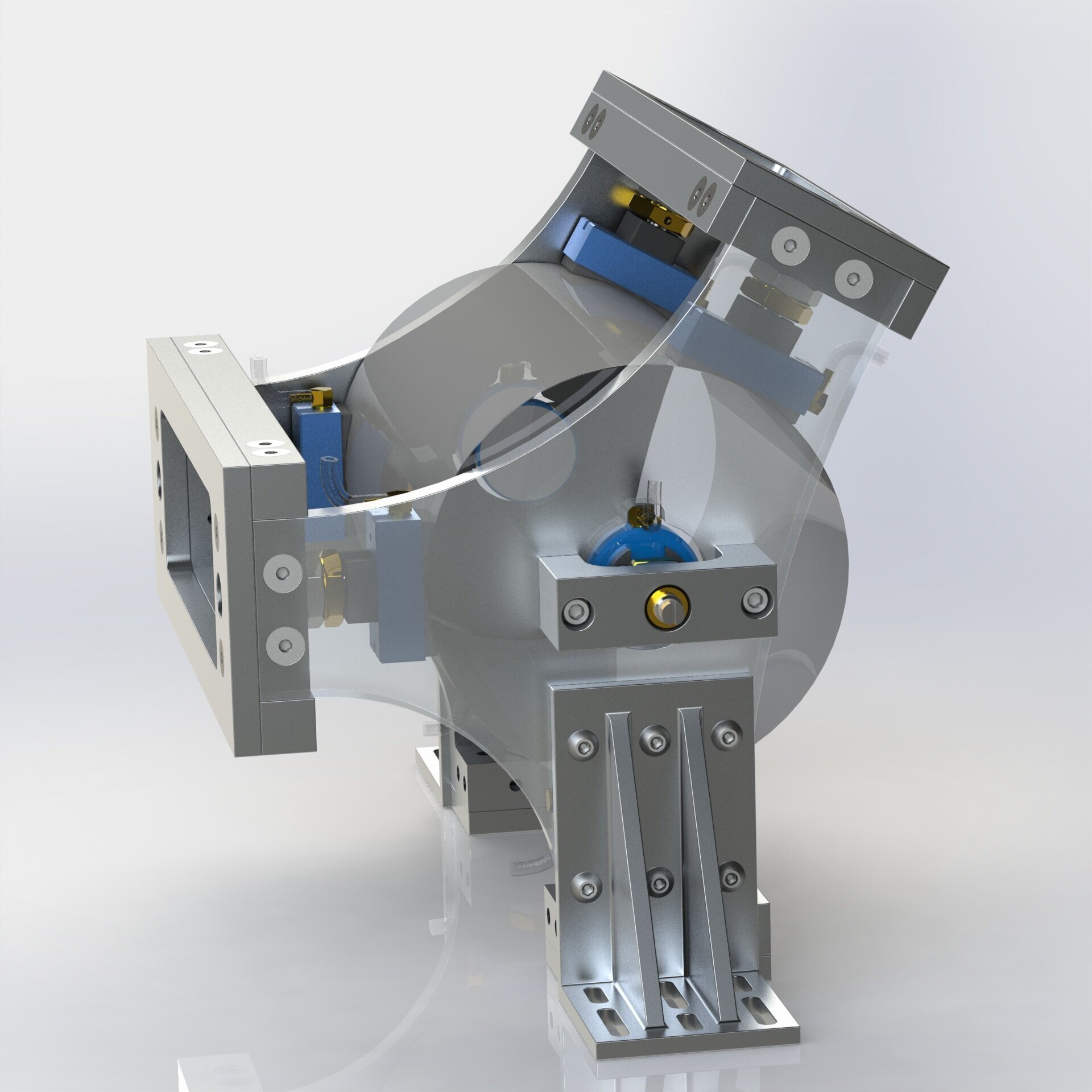

Stirling engines are neat devices, as all you need to do is place a little candle underneath them to make them run. The temperature difference between the flame-heated front part of the chamber and the air-cooled heat sink at the back of the chamber allows for an expansion and compression cycle to do work on the piston, which turns the flywheel. Because we were required to make nearly every part of the engine from stock material, I learned how to use manual mills and lathes, as well as CNC ProtoTRAK mills. Additionally, I gained an understanding of other, more specific manufacturing techniques, such as lapping and brazing.

Results

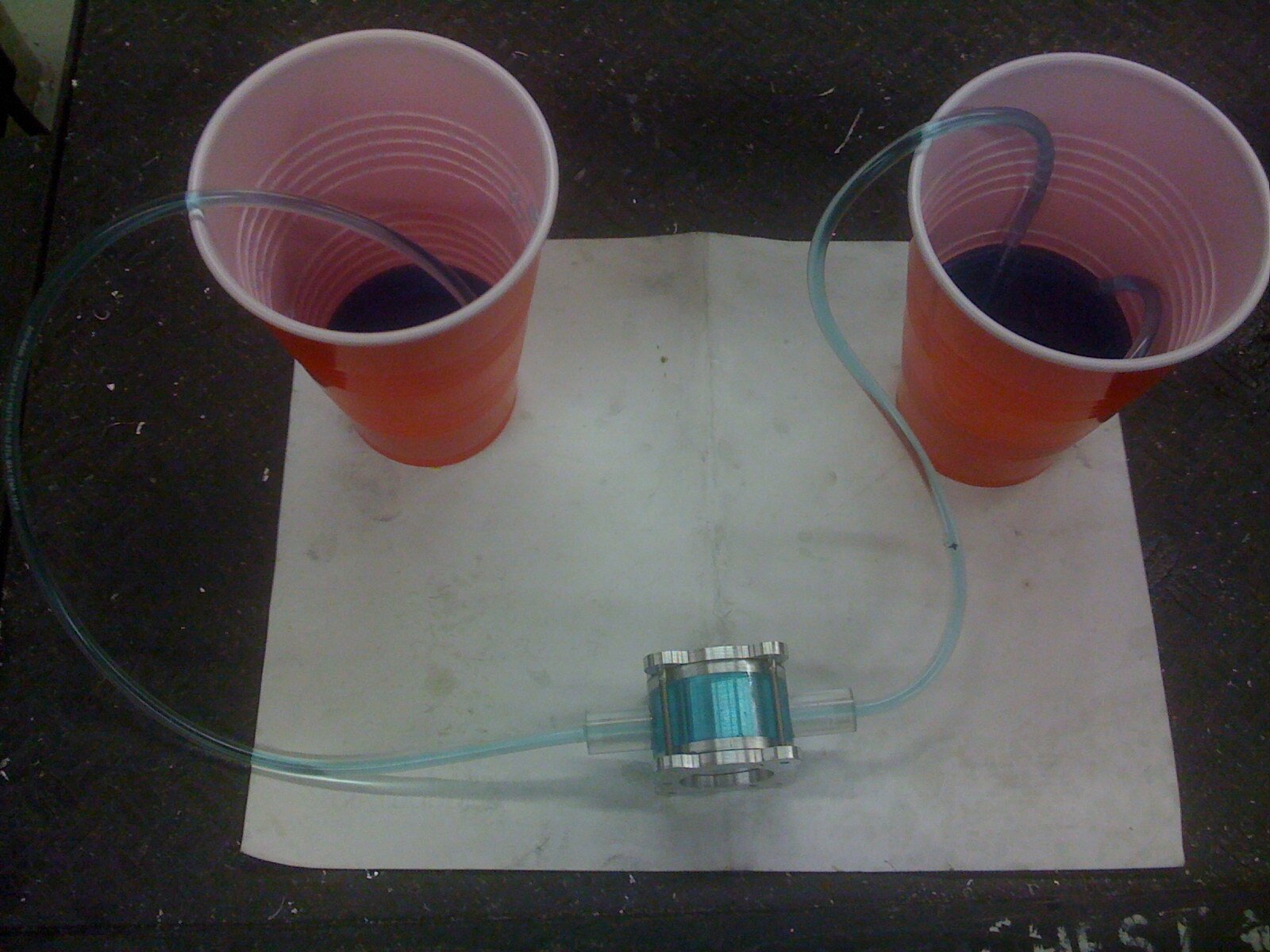

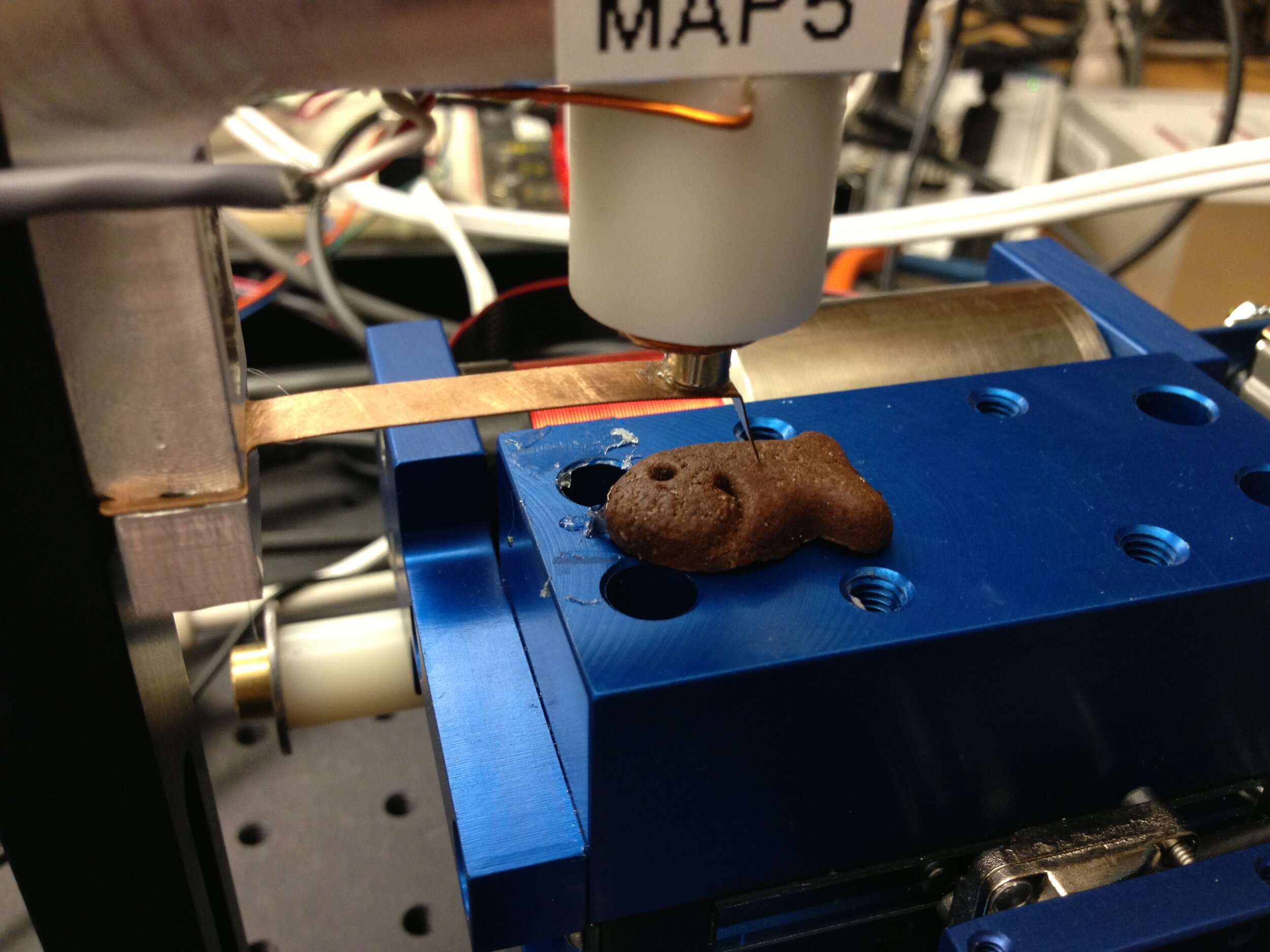

Using a butane torch, my engine reached 1037 RPM, and using a candle it was able to run at 600 RPM. In order to increase its speed, I decided to replace the air-cooled heat sink with a custom designed waterjacket that increased the temperature difference in the engine. Using a basic siphon to flow water through the jacket, I ran the engine again and it maxed out above 1200 RPM. Because of my strong performance in the course, the professor asked me to be the TA for it starting the next semester, my sophomore fall. As a TA, I helped the professor to redesign the course in such a way that the students could customize their engines in countless different ways, and we started to get some really creative and beautiful results.