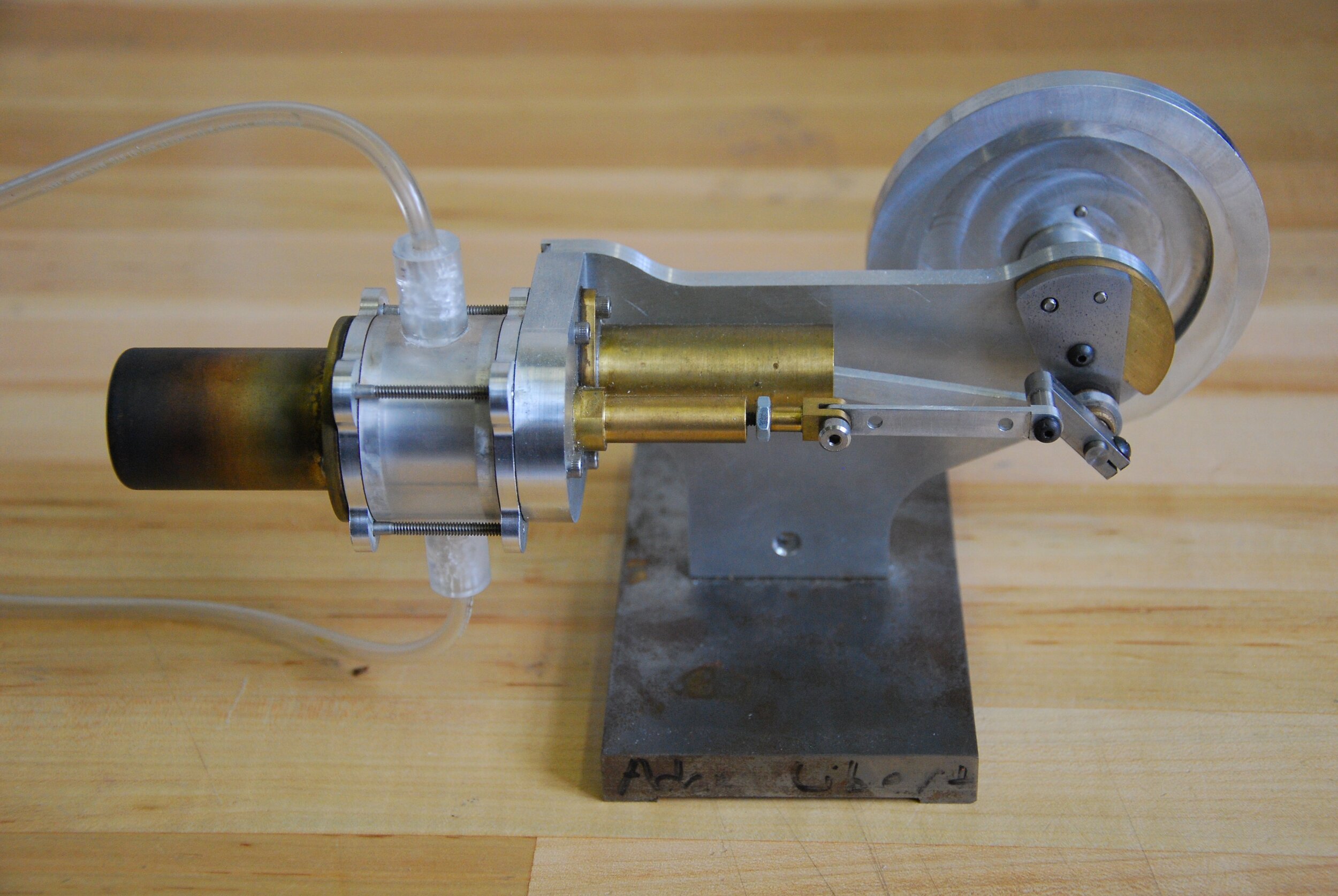

Precision Desktop lathe

Elements of Mechanical Design Course Project - MIT (2013)

Objective:

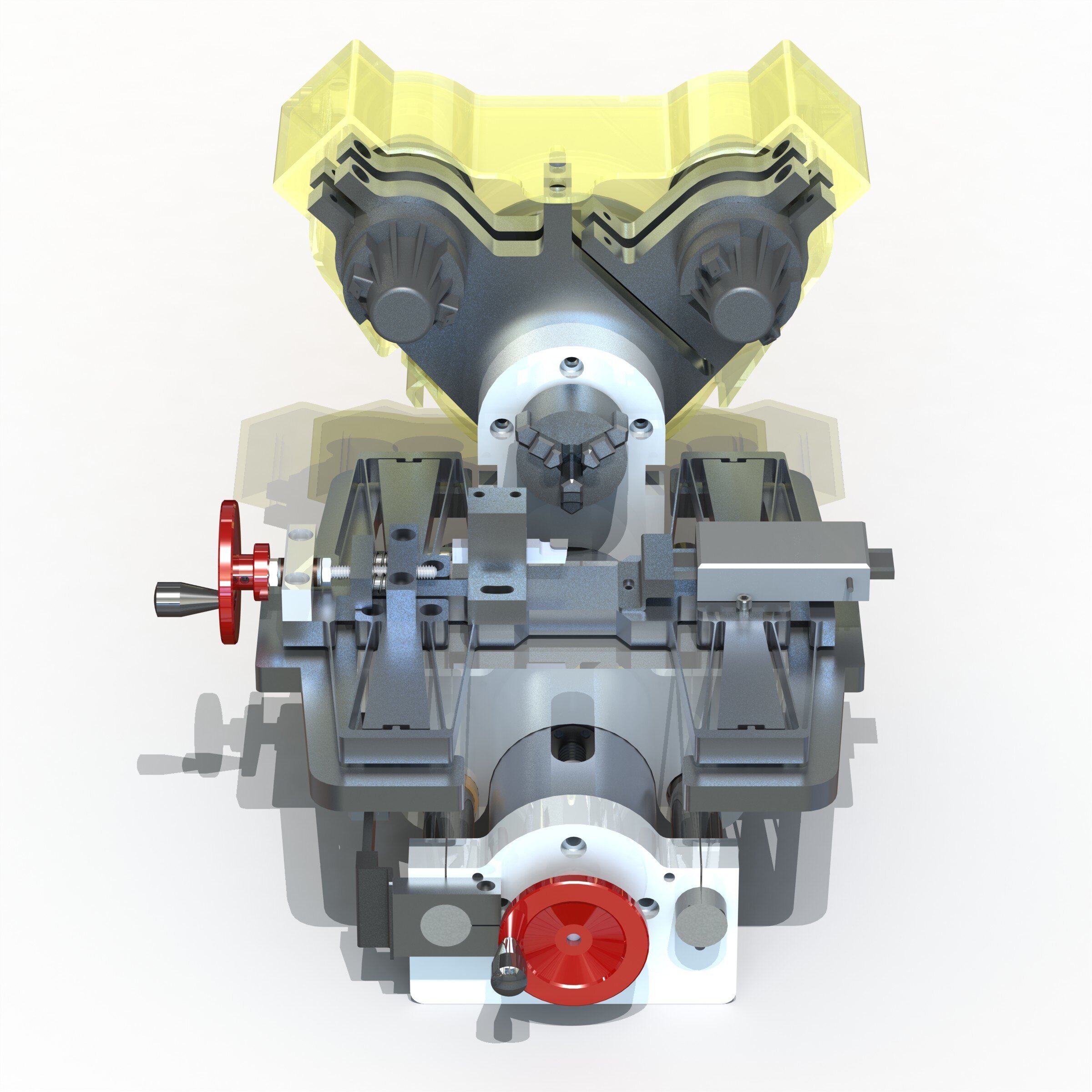

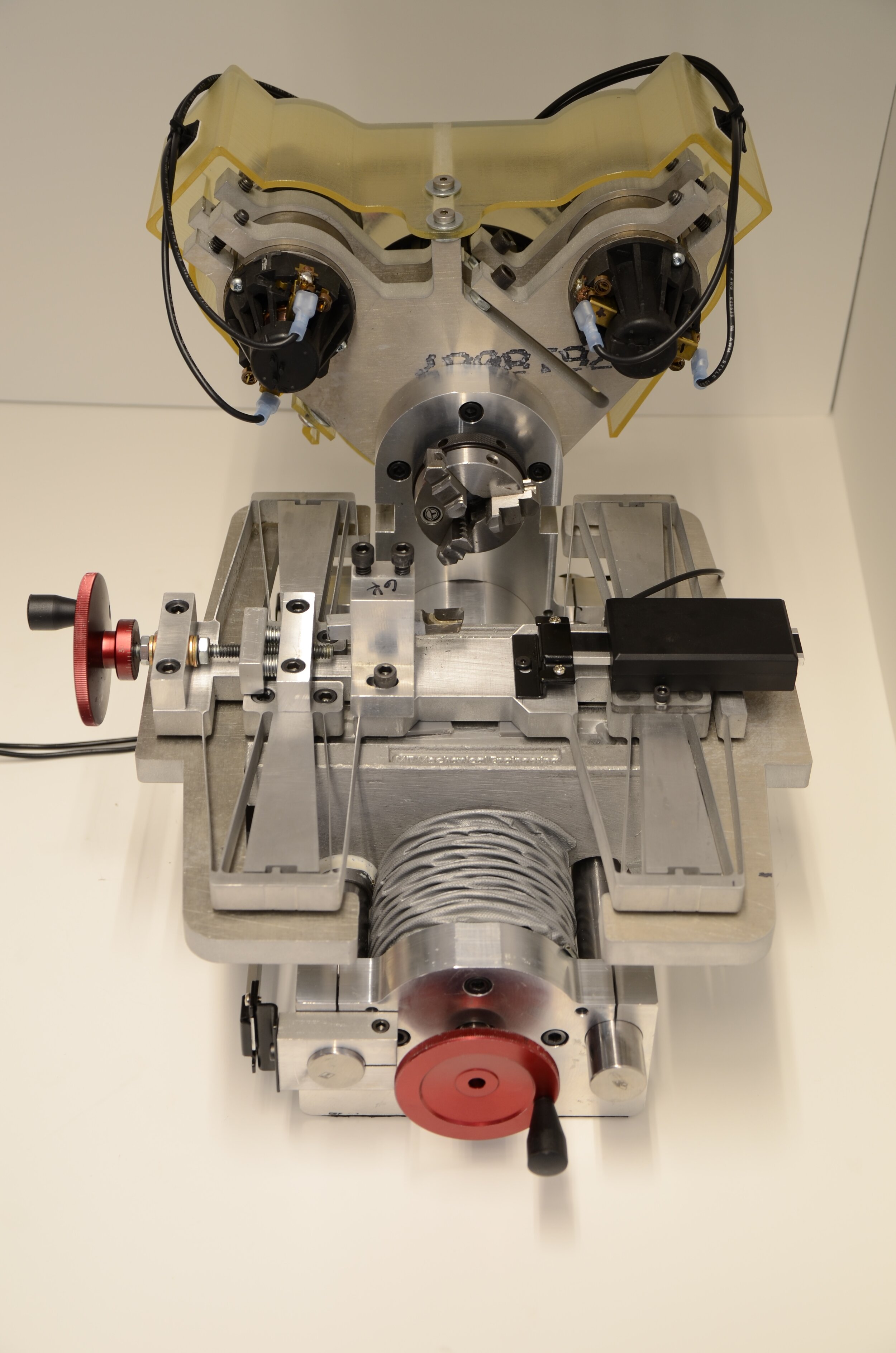

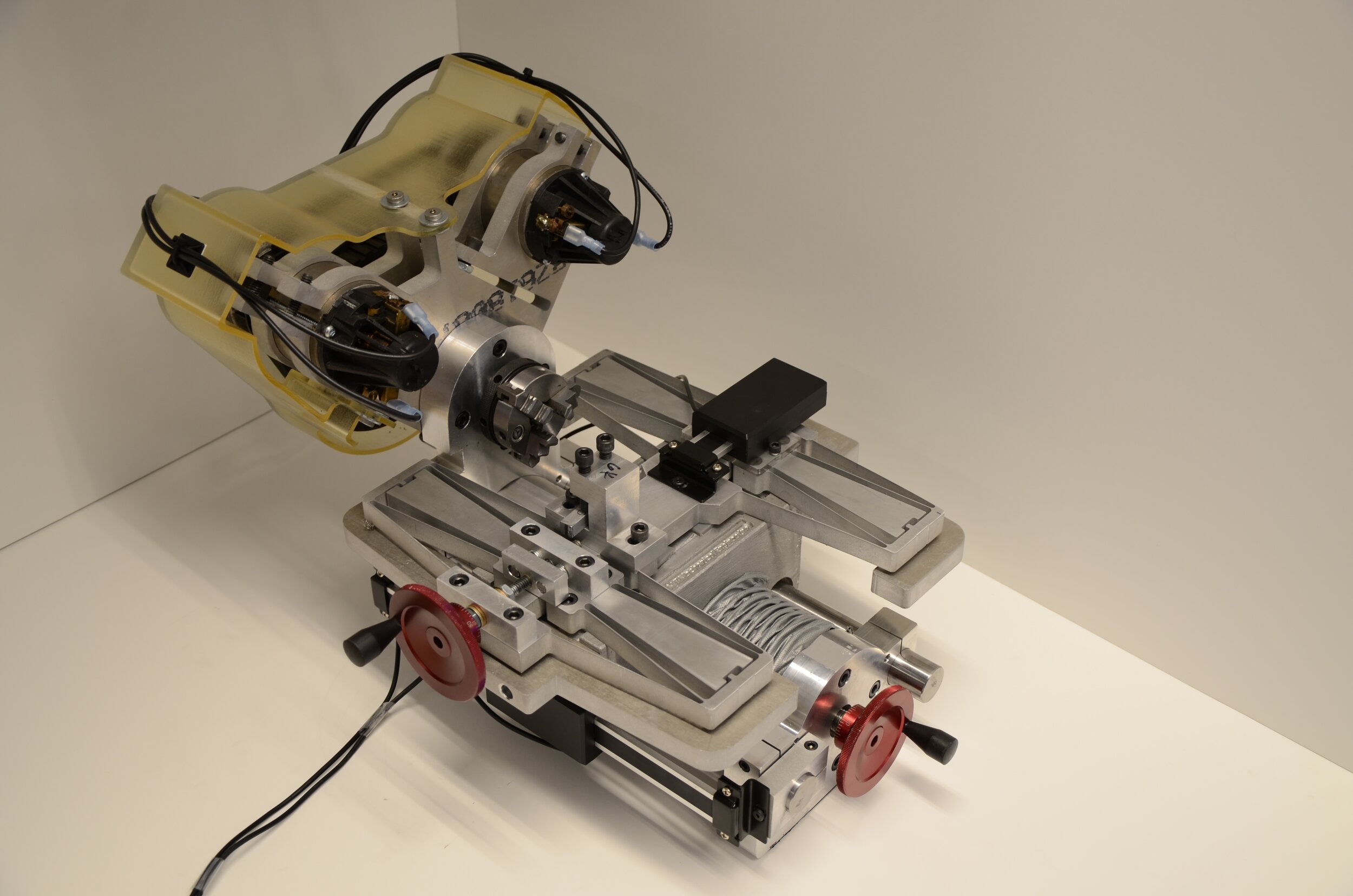

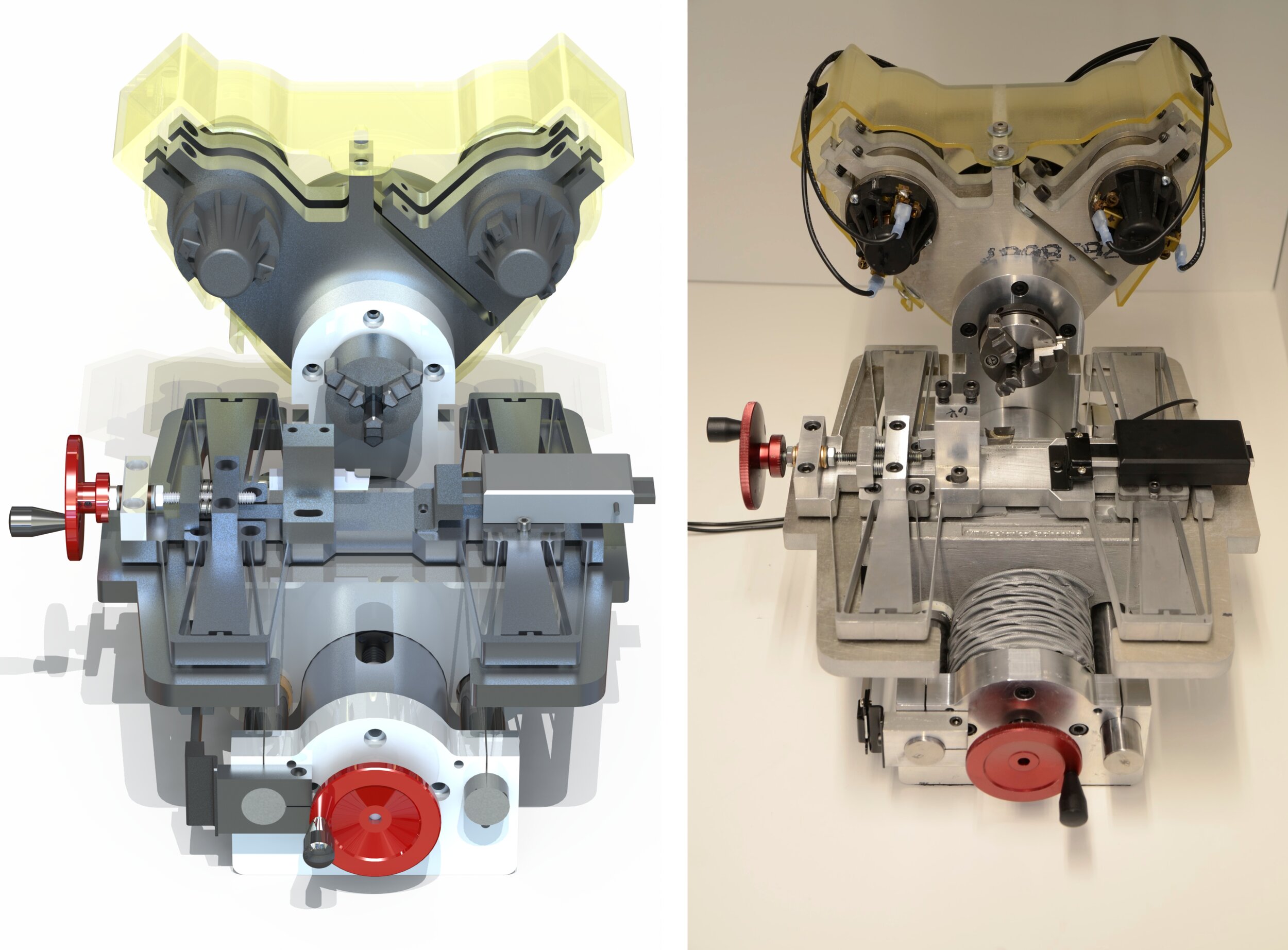

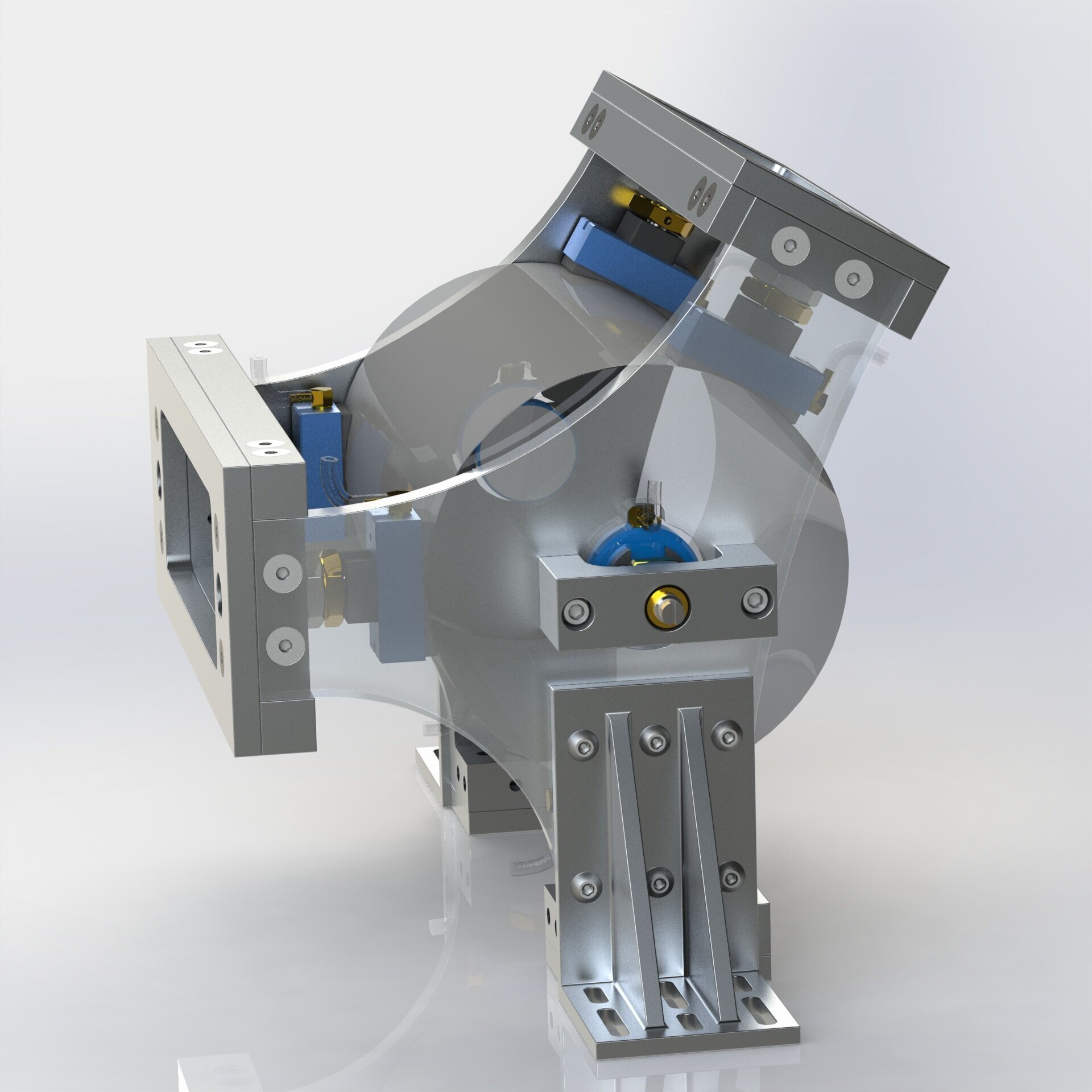

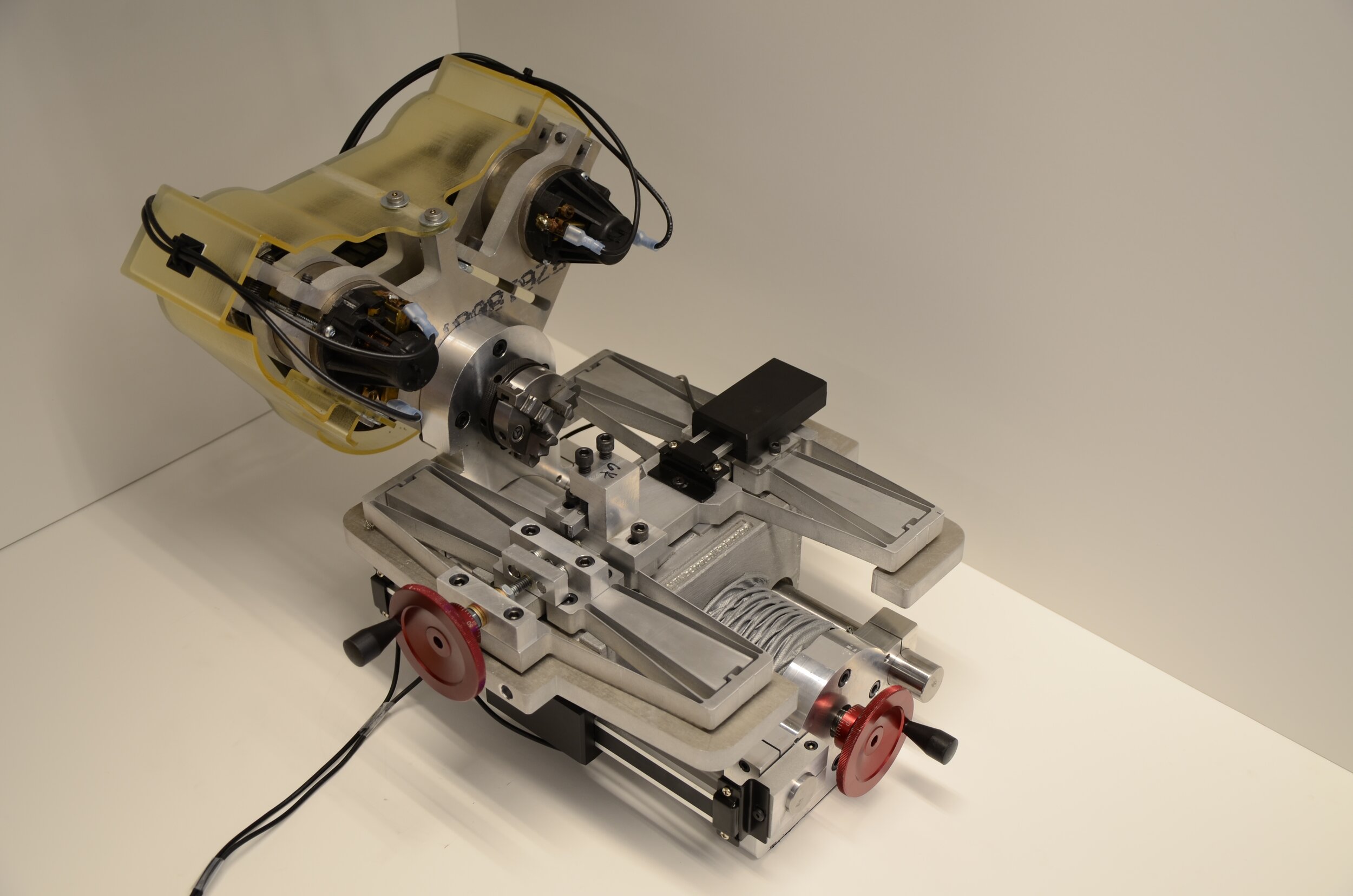

Our goal was to design and fabricate a desktop metal lathe capable of turning aluminum with high precision.

Project Details:

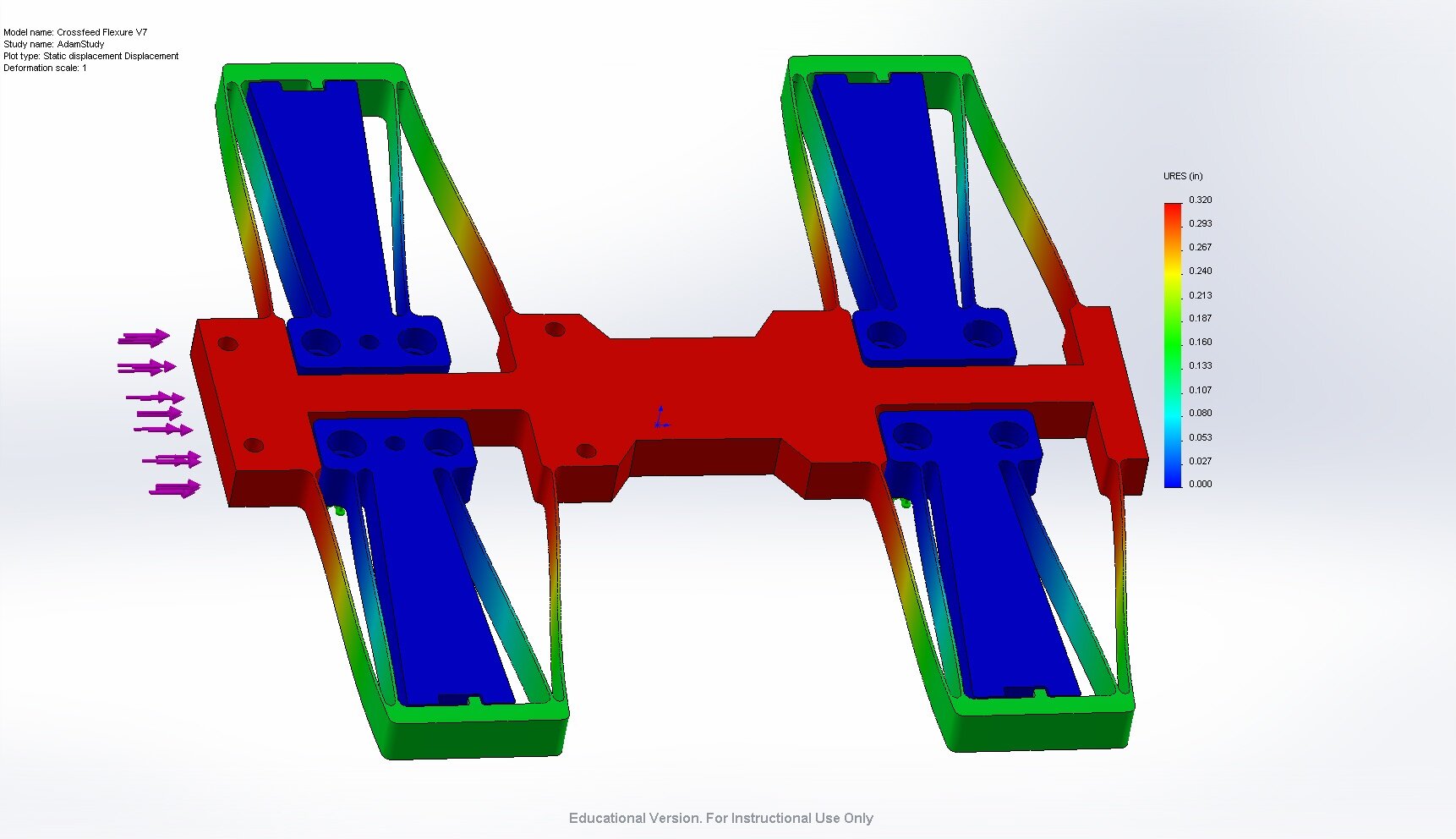

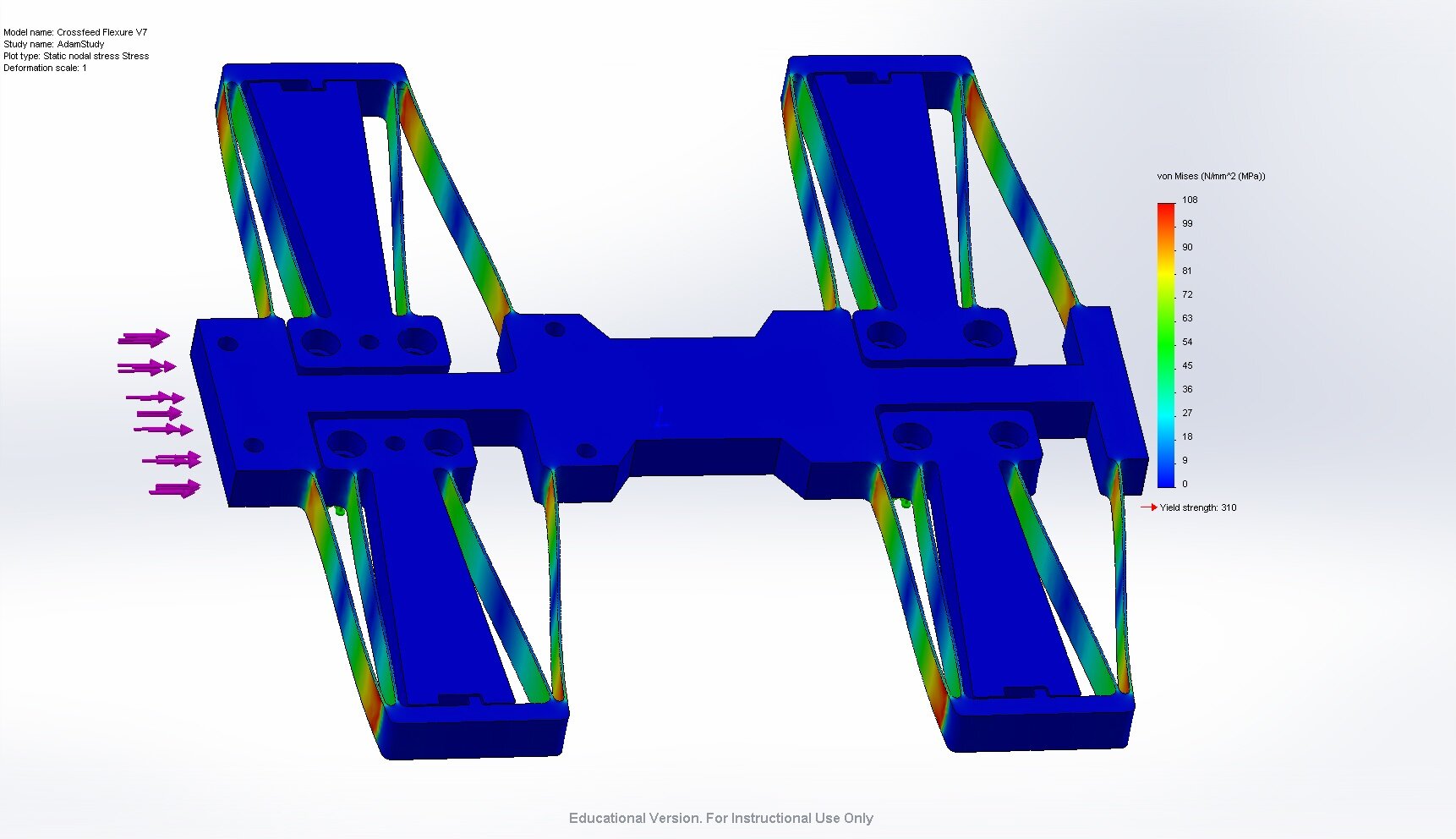

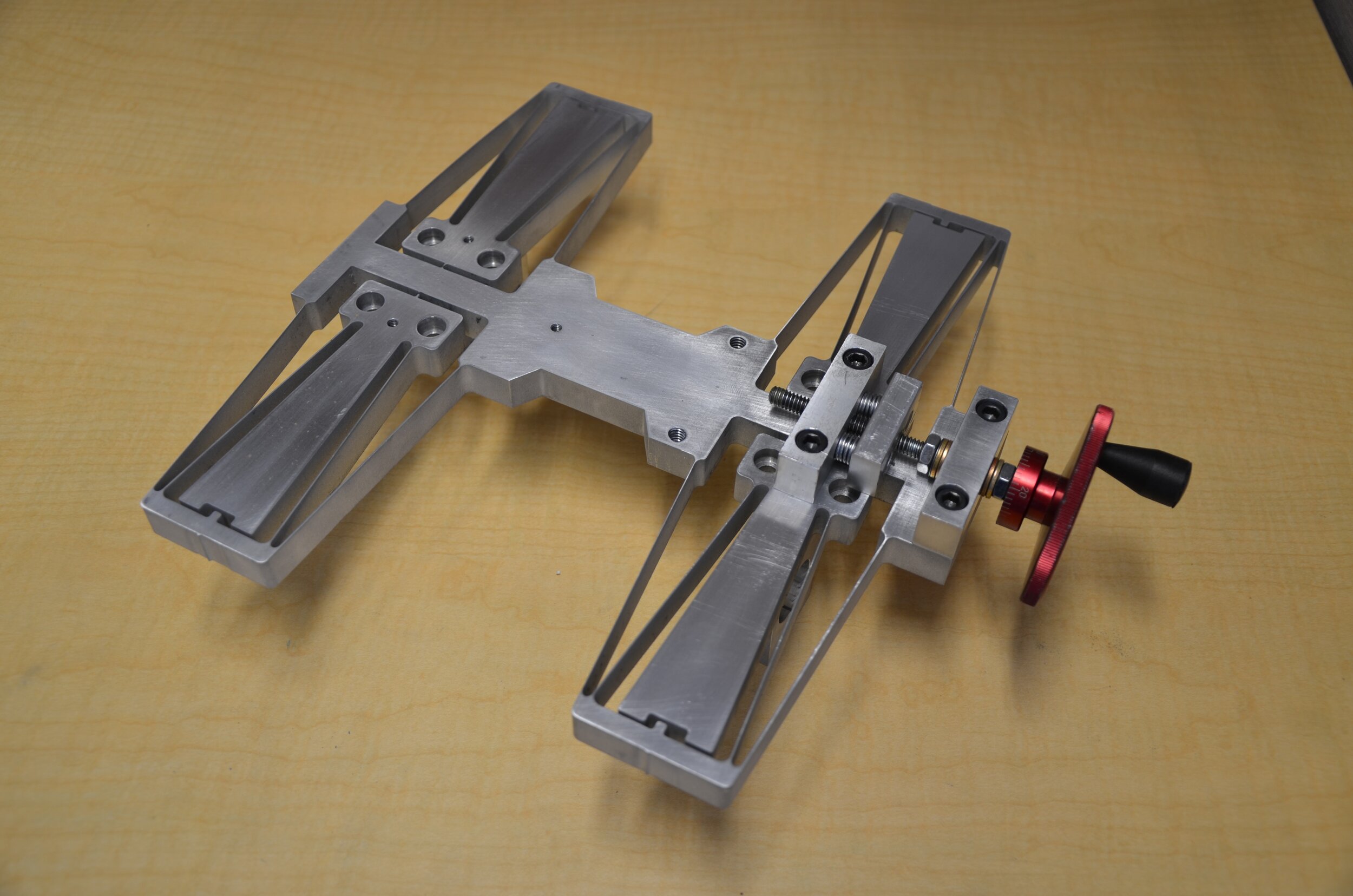

I was appointed the “Machining Guru” of our group of seven students, so I took charge of most of the CAD/CAM work and oversaw the fabrication of every part in the lathe. For this project, we had to think critically about every parameter of the machine, as we needed to be careful to design for a given safety factor, but also not overdesign. The project was rooted heavily in analysis and FEA simulation, with every design decision needing to be backed up by calculations showing the expected stress, deformation, fatigue life, and thermal expansion. I learned a lot about power transmission, bearing selection, bolted joints, flexure design, and a variety of other elements of machine design.

Results

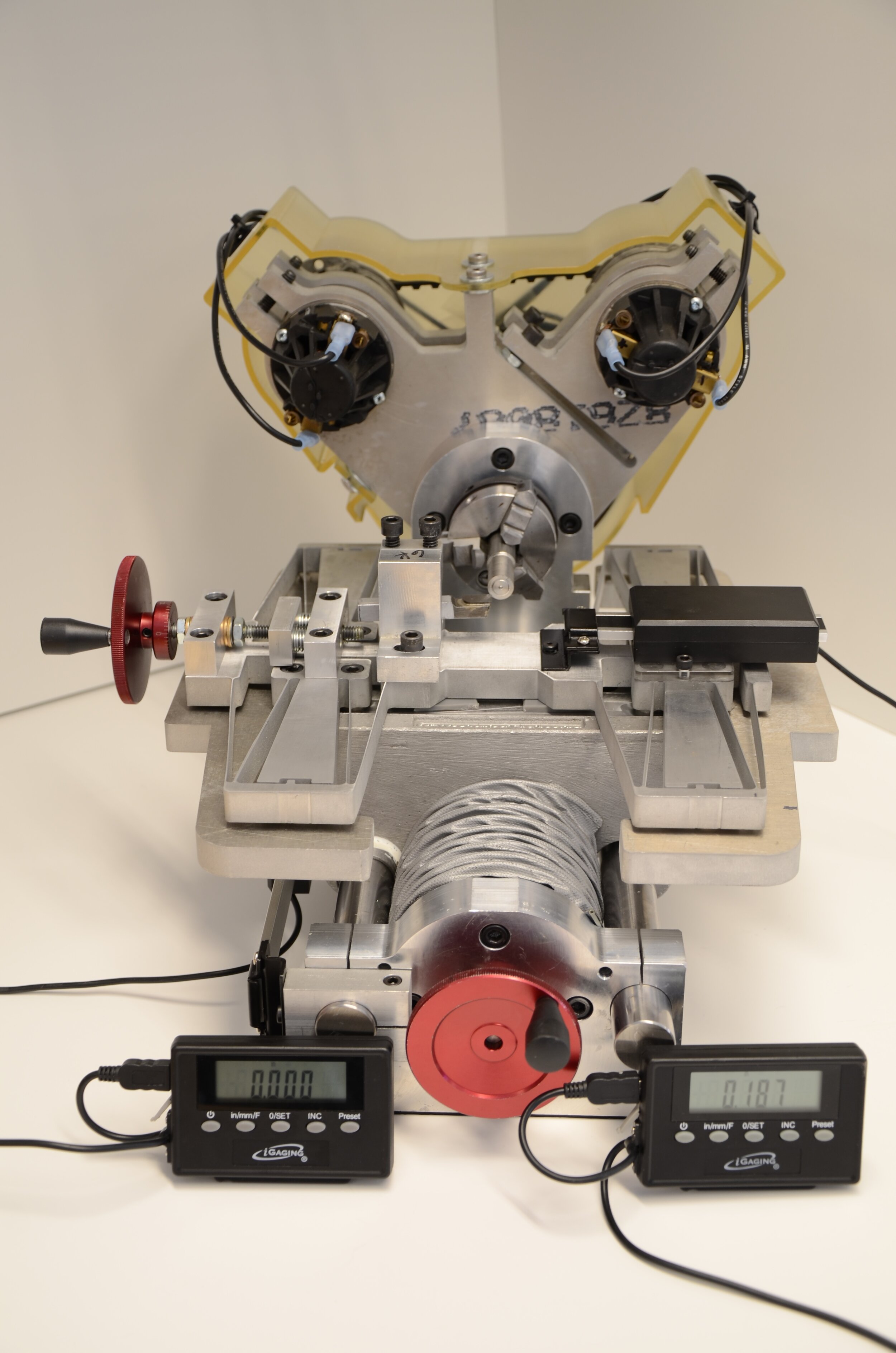

Our lathe was driven by dual 1/4 horsepower DC motors, had DRO position readouts, and was capable of turning aluminum and steel to a tolerance of 0.002”. After demonstrating our lathe, it was put through the “death test” wherein the professor stood on top of it, dropped it from desk height, and hit it with a sledgehammer. Even after all that, it still continued to turn pieces to the same tight tolerance!