Low Cost Water Jet

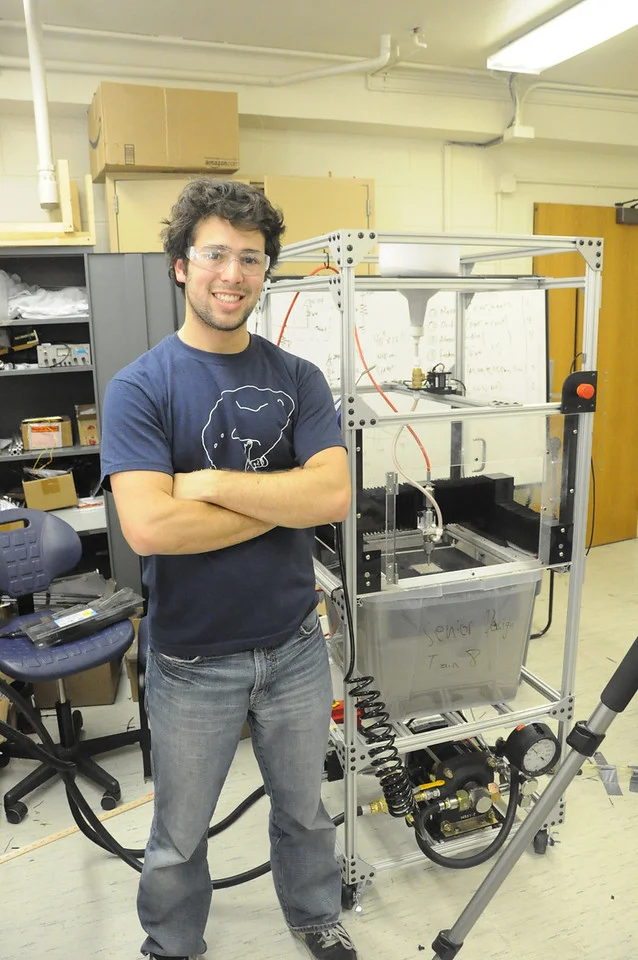

Senior Design Project – University of Pennsylvania (2012)

Objective:

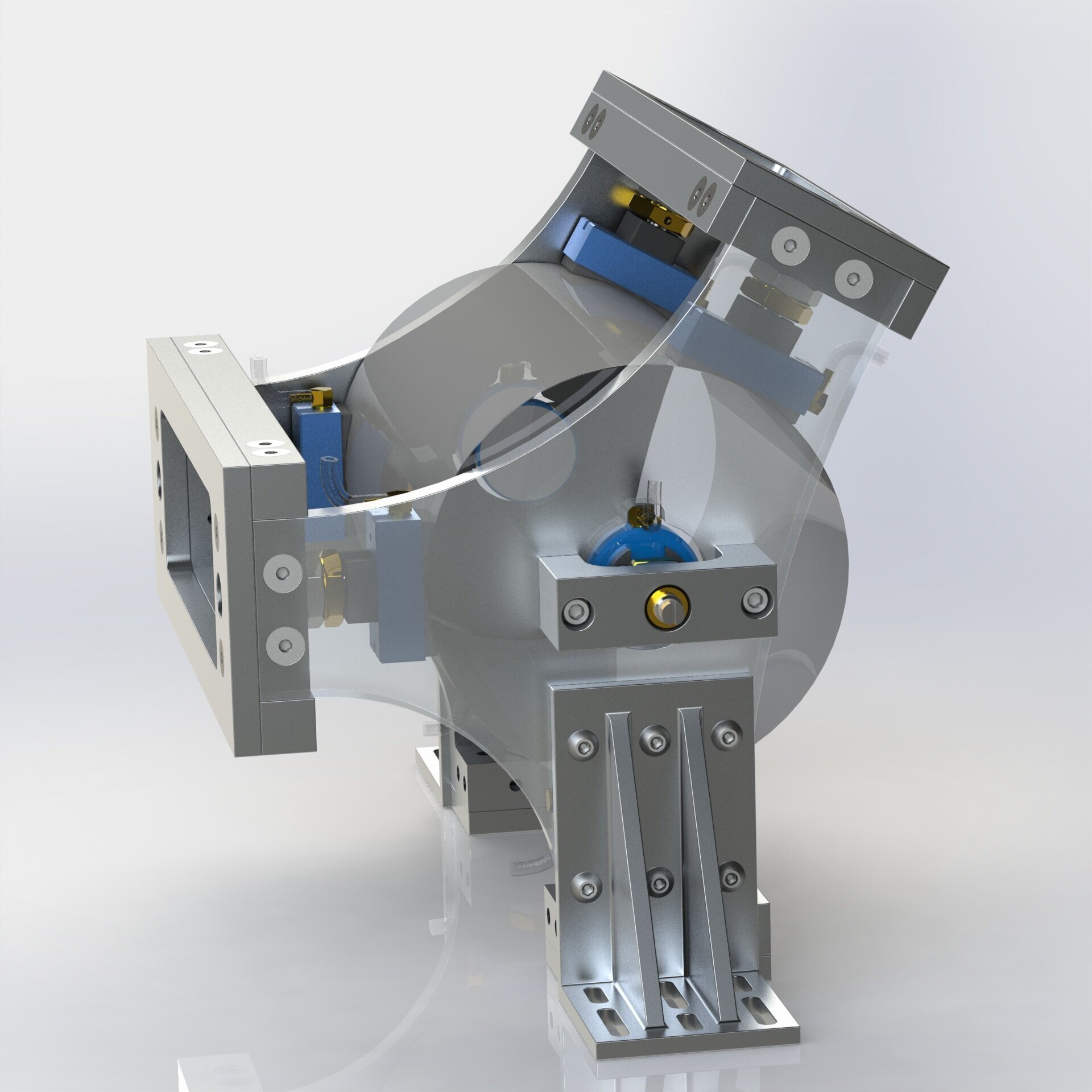

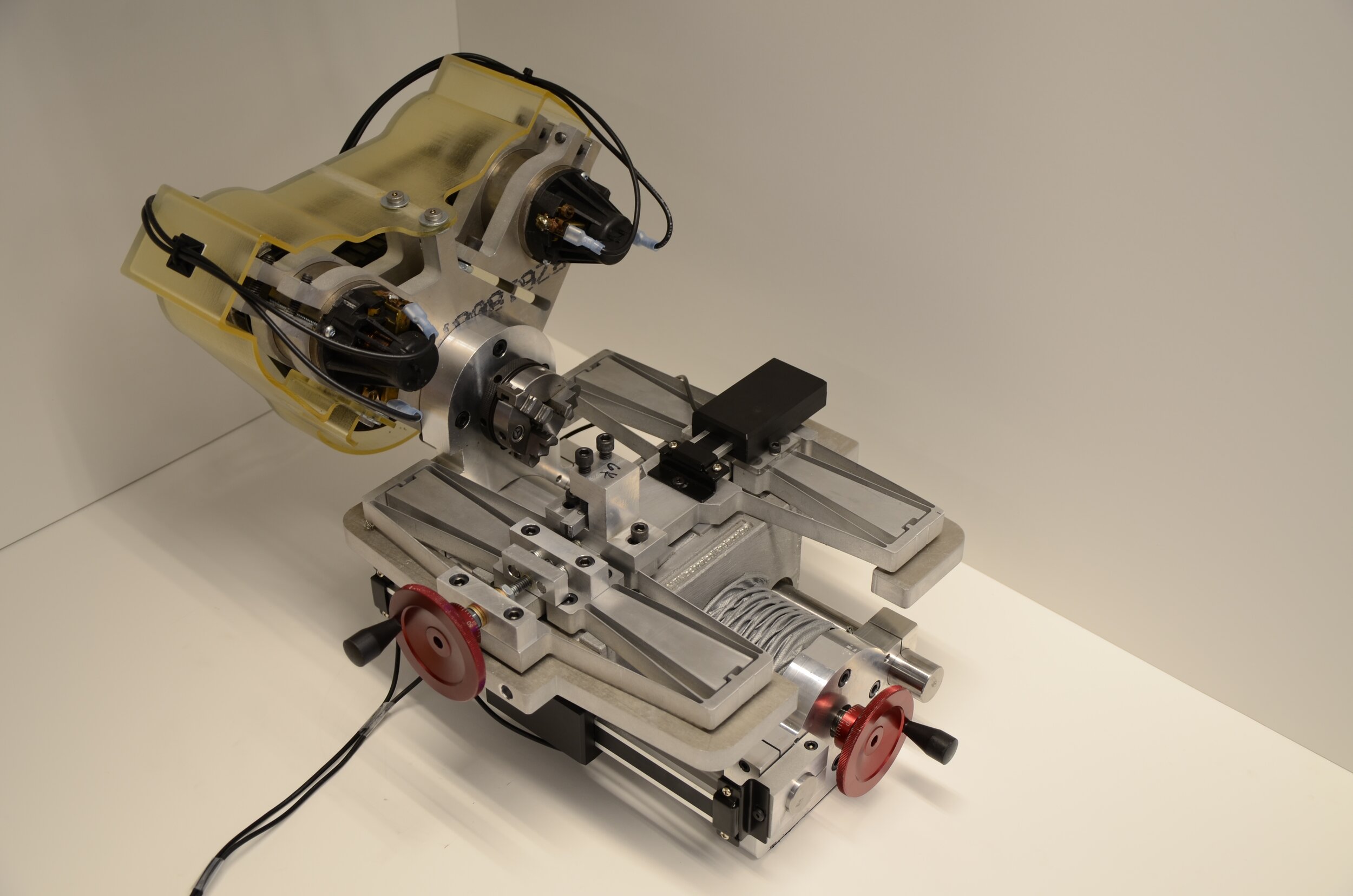

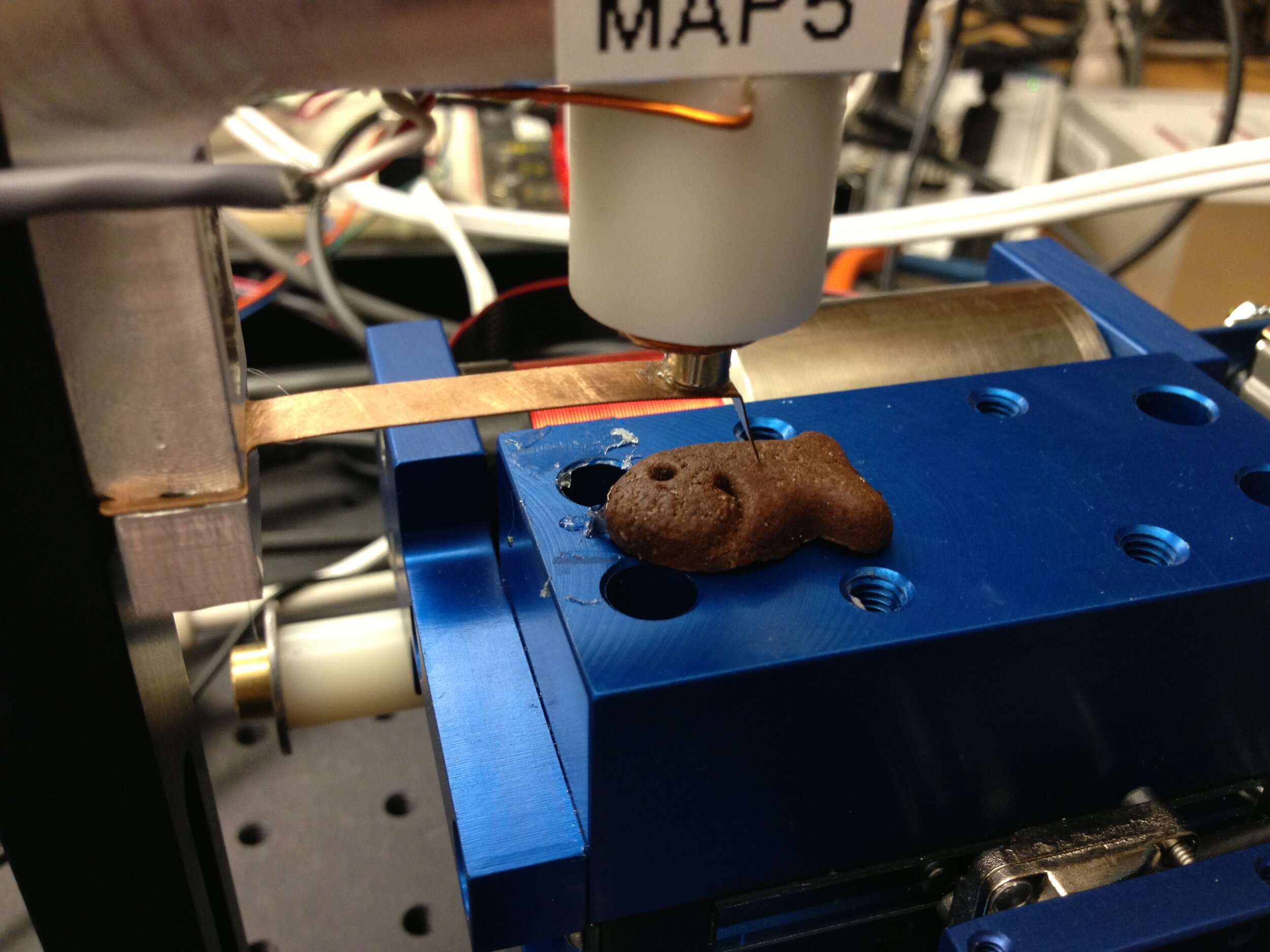

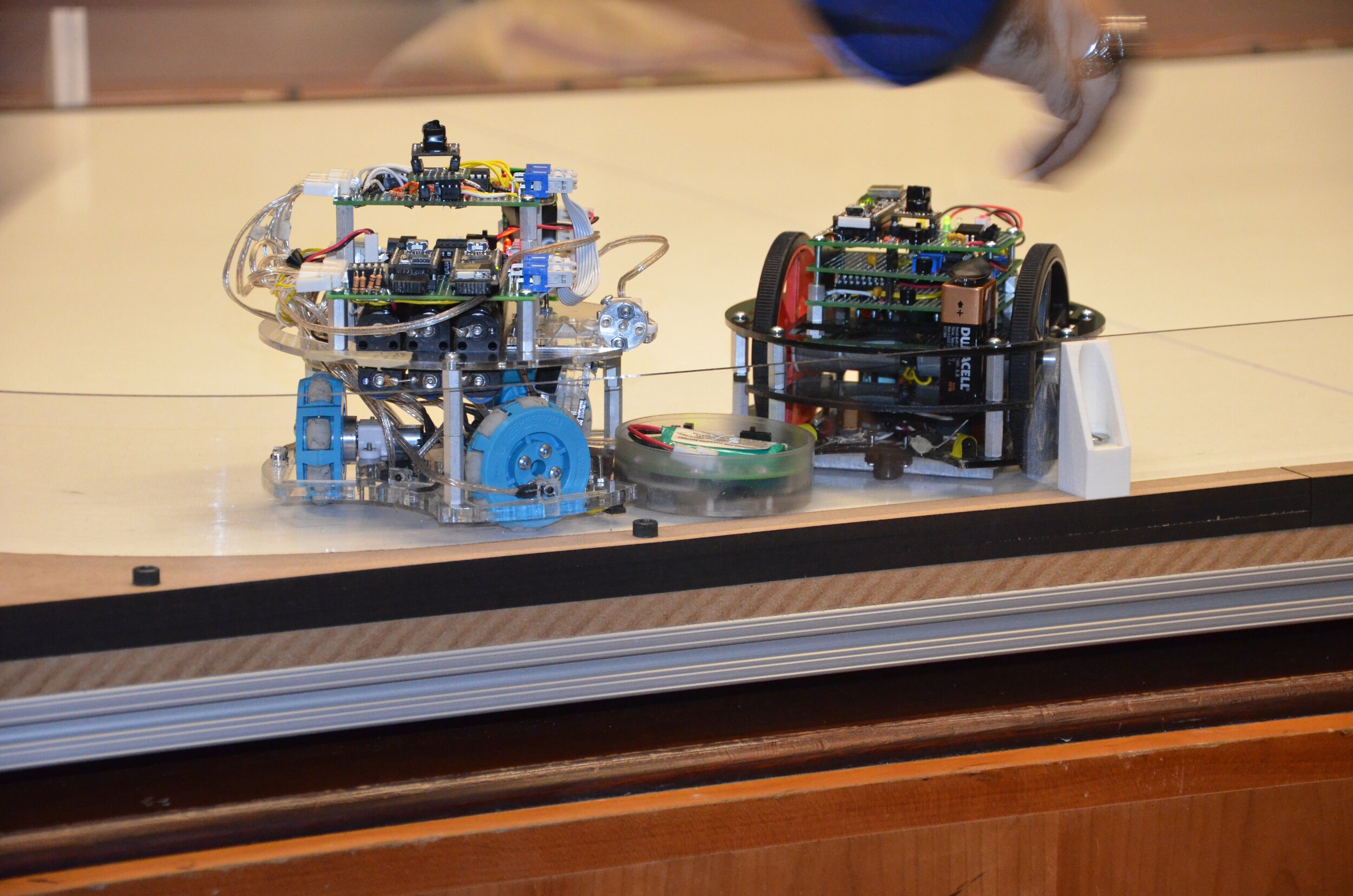

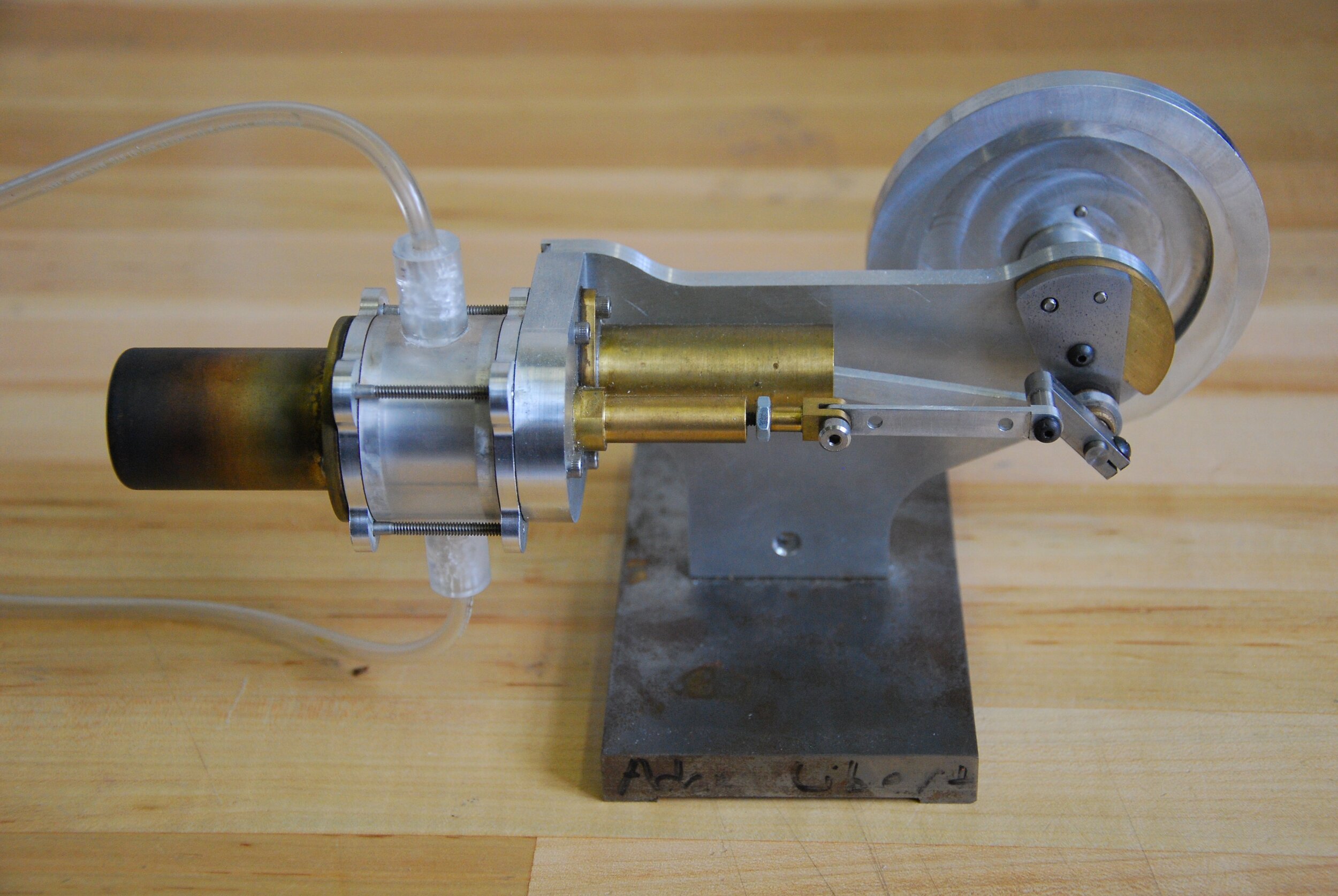

My team of five decided to create the first ever, small-scale, low-cost, and easy-to-use waterjet cutter, finally making this great technology available to hobbyists and small businesses on a budget.

Project Details:

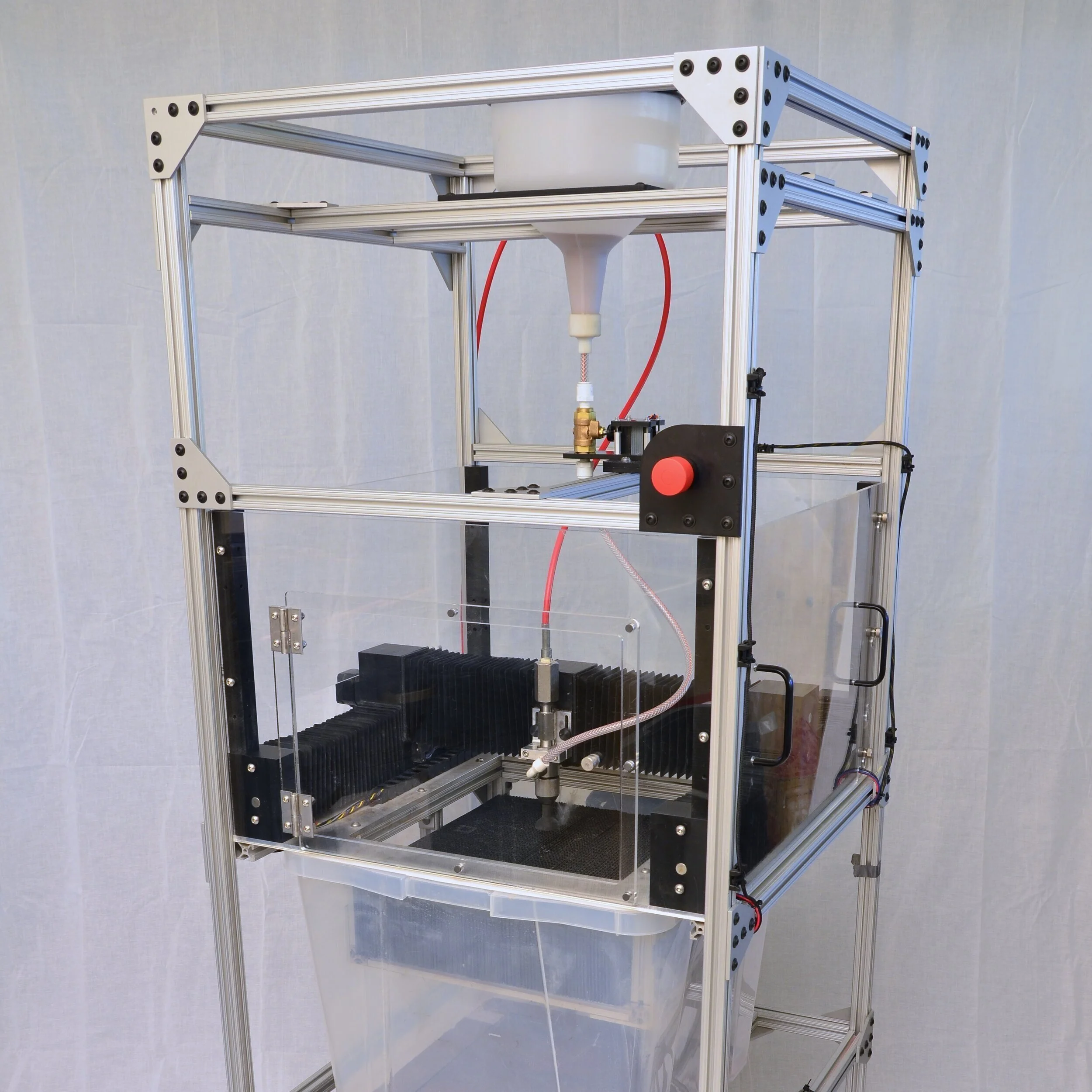

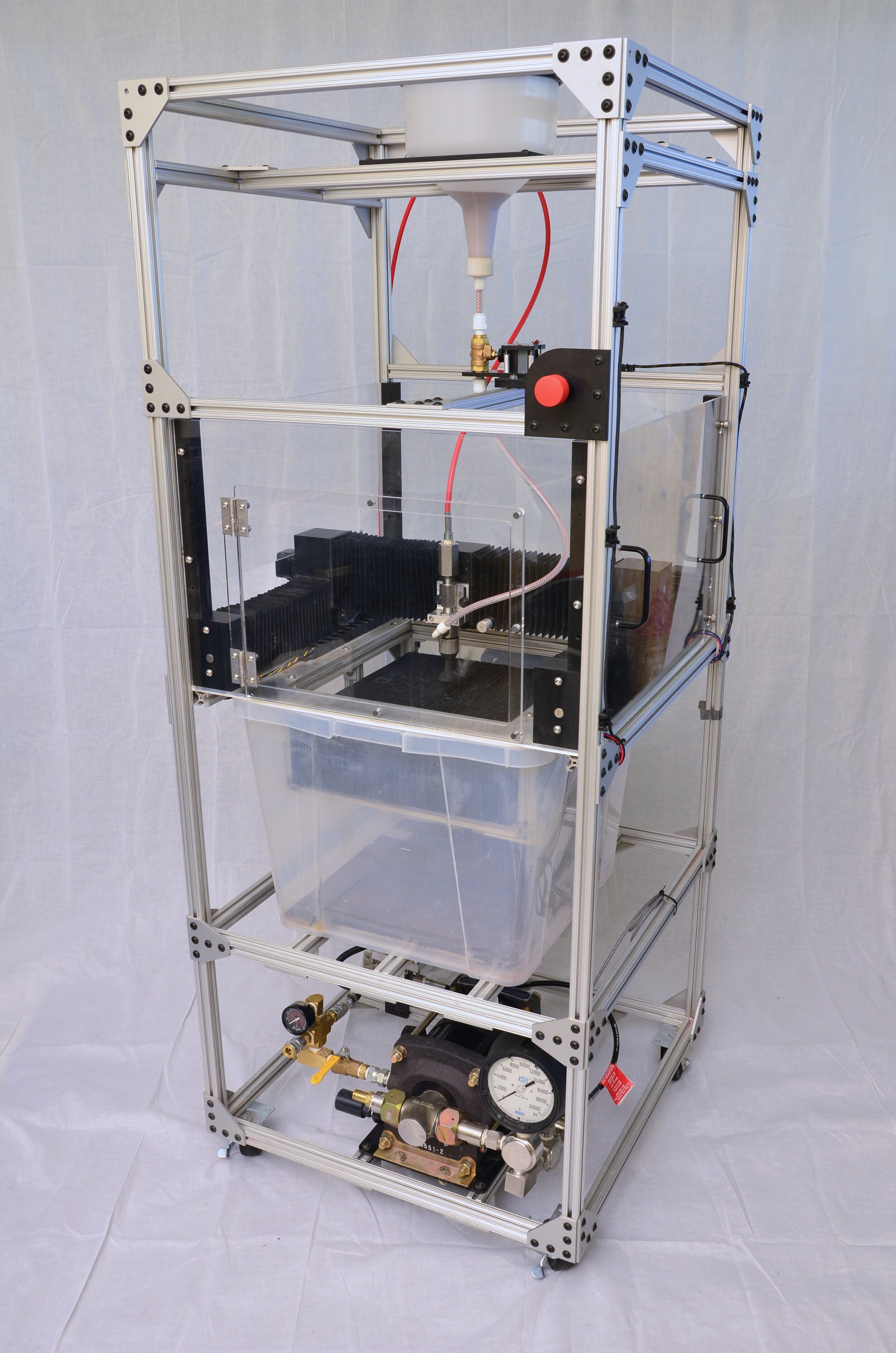

I was the lead mechanical designer on this project and custom designed a fully waterproof and environmentally sealed XY gantry that would be able to withstand the water and abrasive from the waterjet. The waterjet has a cutting work space of 12”x14” and yet the machine is entirely self-contained to a footprint of only 2 feet by 2 feet, meaning that it can be easily rolled through a doorway and fit in the corner of any room. As well, it requires only a typical electrical outlet and shop air supply to run, making it a feasible option for universities, hobbyists, and small businesses with a budget of $5000 or less. The waterjet is low maintenance, requires only minimal training to run, and is able to cut through 1/4” aluminum and 1/8” steel to a tolerance of 0.005”.

Results

This project won the Mechanical Engineering Senior Design competition, and each of us on the team was presented with the Gemmill Award for Outstanding Creativity.

Update

This project is being developed as WAZER, the world's first personal waterjet. Read more about it here: WAZER

Team

Adam Libert, Nisan Lerea, Nicholas Bartlett, Carlee Wagner, Neel Doshi, and Jonathan Fiene (advisor)