Dragon water Stability system

Lead Engineer – SpaceX

The Crew Dragon capsule floats in the ocean after successful Demo Mission 1. An approximate center of mass of the capsule is marked in red, with the gravity force acting downwards on it. Additionally, the buoyant forces are represented by the arrows acting on the underwater portion of the capsule. The relative location of the center of mass to the center of buoyancy defines the attitude at which the capsule sits in the water.

Objective:

Ensure capsule remains in the upright Stable-1 position after splashdown, such that the crew inside is kept at a healthy angle with respect to gravity given their deconditioned state after being on orbit for months.

Project Details:

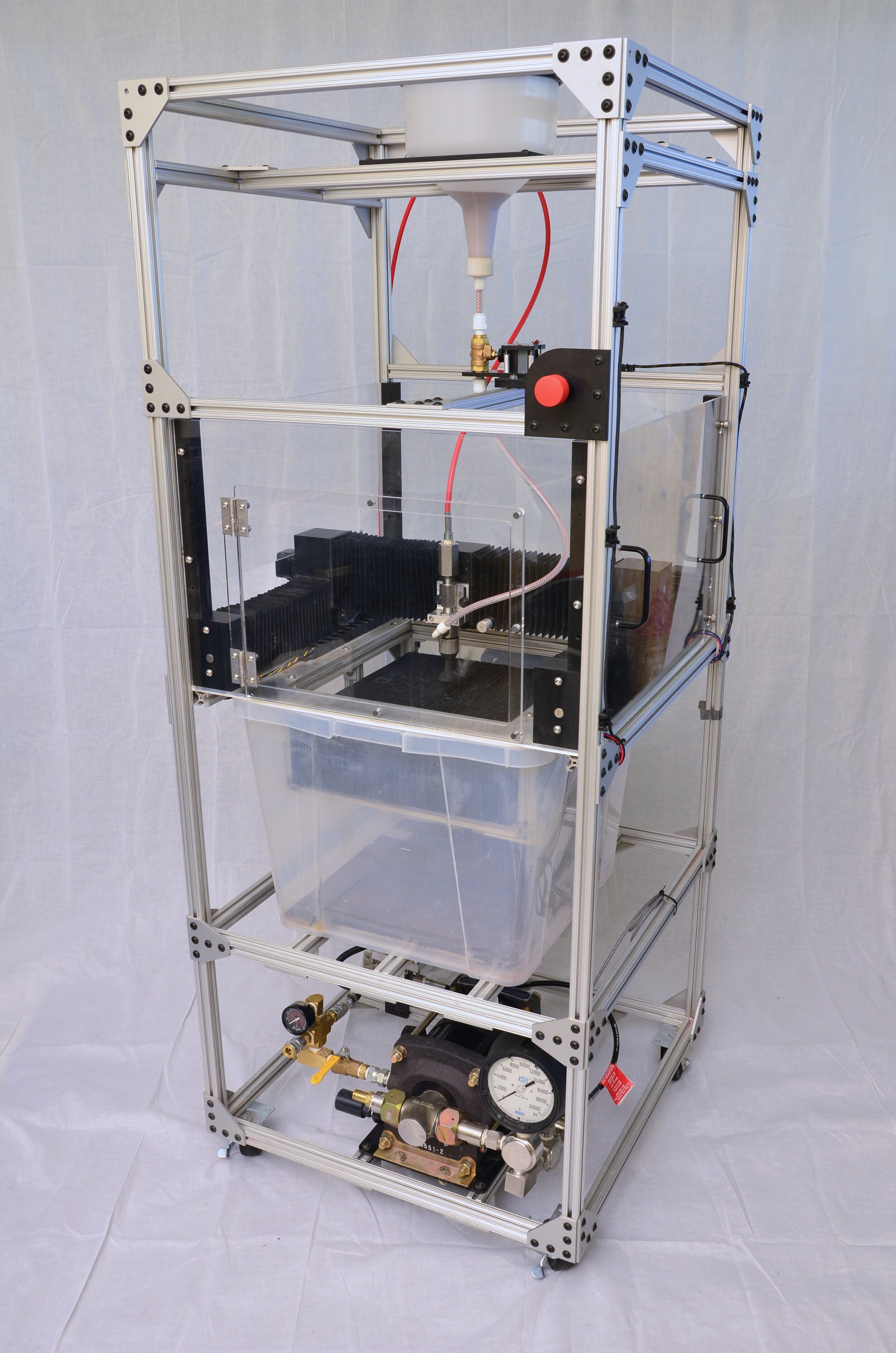

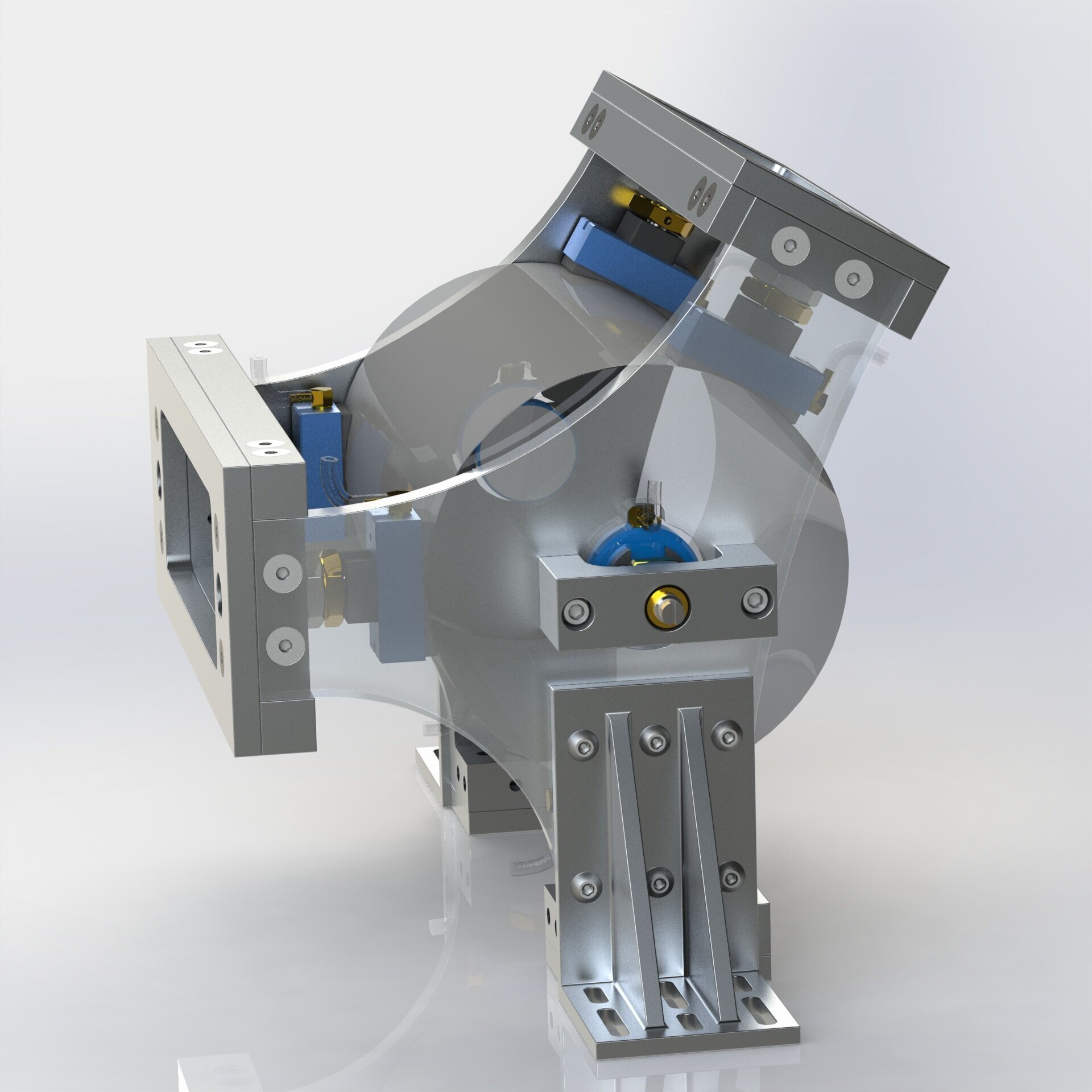

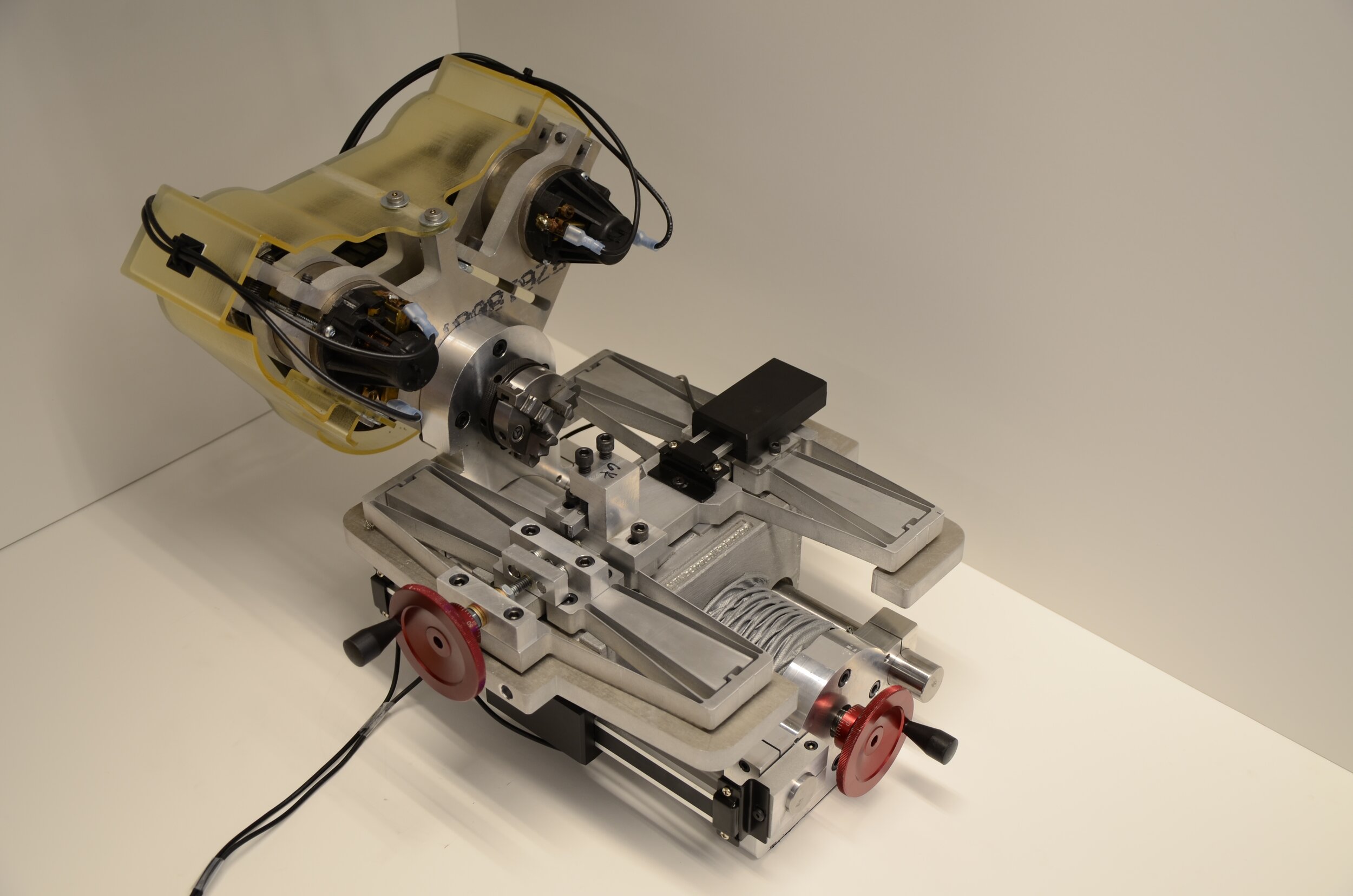

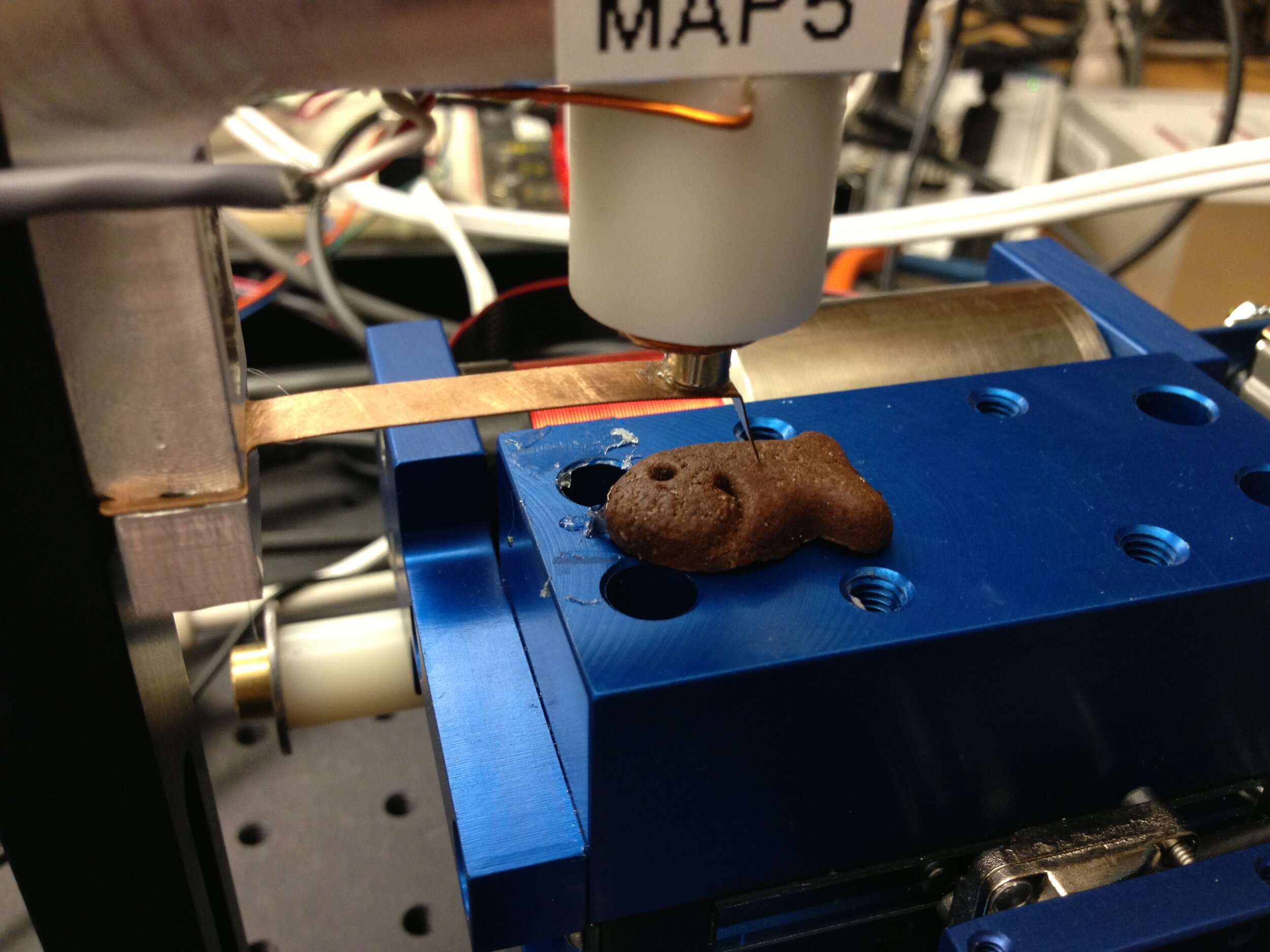

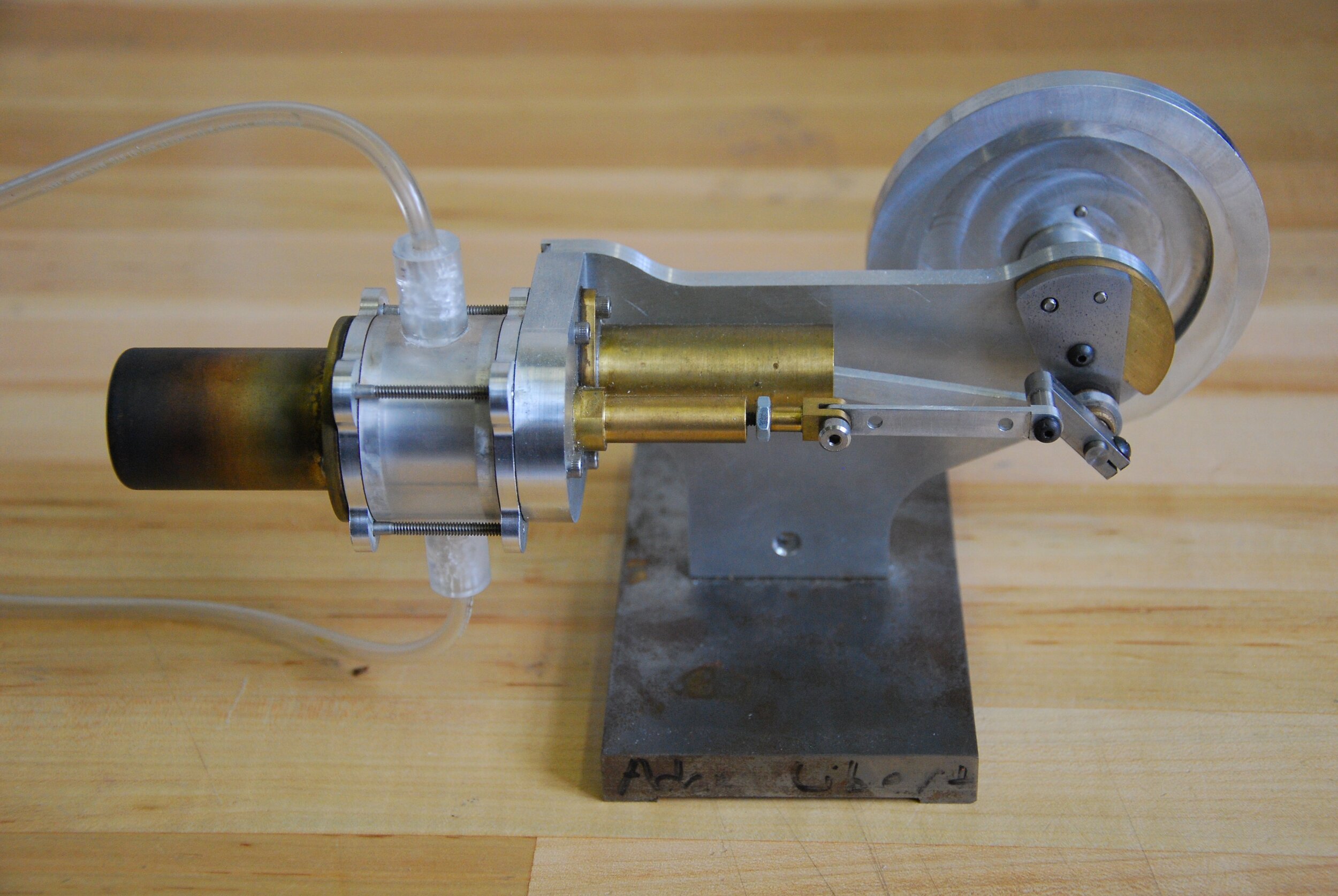

After multiple previous methods of post-splashdown capsule stabilization had failed qualification, this project was one of the top combined technical and schedule risks for the Dragon program. The Director put me in charge of four engineers to solve the critical-path ocean stability problem on an aggressive timeline. We built models of the capsule stability points in the ocean, brainstormed from first principles ways to improve stability, and development-tested various solutions to retire risk and down-select to the final concept. Although we identified an unconventional system, it was based on simple physics principles and we quickly proved out each component of the system. Using scrappy test setups, we continued on to sub-system and ultimately full-scale system level tests to validate our models and ensure proper operation.

Results

We aggressively developed, qualified, certified, and integrated the system on schedule. I feel particularly proud of the system because of how successfully it combined components from multiple disciplines: fluid systems, specialized valving, non-explosive actuators, electromechanical pumps, soft goods, structure, and thermal protection – all uniquely designed and qualified by my team to the satisfaction of both in-house and customer requirements. This was the first system of its kind in many regards and has already served as an example for following development programs.

Note: Only publicly released photos and information are presented here.